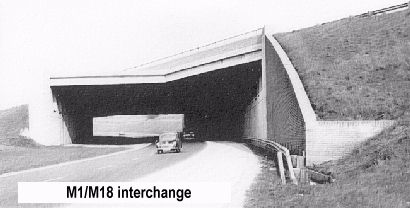

Leaving Nottinghamshire, the M1 motorway passes to the east of Aston to the interchange with the A57 Worksop - Sheffield Trunk road and then joins the M18 at Thurcroft. At Thurcroft the motorway interchange provides an east-west link between the M18 and the "West Riding" length of M1 to the north.

The M18 interchanges with the A631 Gainsborough - Rotherham Trunk Road and then turns eastwards passing under some five bridges to join with A1(M) Doncaster By-pass at Wadworth.

With this section of the route being predominantly in the coal measures, problems of dealing with abandoned mine workings at shallow depth and the subsidence to be expected from deep mining largely affected the design detail. The effects of mining subsidence mitigated against a concrete or composite road construction and a fully bituminous paving was adopted. A single main sewer system under one verge, wider than normal, was used with high strength pipes and flexible joints. The widened verge permitted easier maintenance. The structures were designed to take account of mining subsidence. This necessitated the introduction of the centre pier in all cases. In general, all bridges are of reinforced concrete, those over railways and some roads being pre-cast. Retaining walls are, in general, of mass concrete, faced with pre-cast concrete block facing.

The Barlborough to Thurcroft Contract M1 of some 6½ miles was awarded to Tarmac Civil Engineering Ltd (now Carrilion Construction) in October 1965 and the 8½ mile Thurcroft to Wadworth Contract M18 to W & C French in January 1966.

The final cost of the contract work done by Tarmac Civil Engineering Ltd (now Carrilion Construction) was £4.56 million and that by W & C French, £5.2 million.

The ground was coal measures throughout, so the whole motorway was designed to cater for mining subsidence, with a flexible roadway and hot rolled asphalt surfacing. Sir Owen Williams were renowned for their dislike and avoidance of pre-cast and prestressed concrete, so all the bridges were fully cast in situ. This, together with the design for subsidence, meant that they were slow to construct, with massive reinforcement which made placing and vibrating the concrete very difficult. Four of the bridges had decks of reinforced concrete supported by a row of reinforced concrete 'rockers' on each abutment. These were about 6 ft. high and 1 ft. 3 in. square in plan, all cast in situ.

At Wales Bar the Motorway was in deep cutting which was expected to be rock capable of self-support for the excavations for the bridge foundations, which were massive. In reality the rock was extremely unstable, and the proximity of dwellings at ground level plus the road diversion to enable bridge construction meant that it was imperative to excavate, rock bolt with mesh, and concrete on the same day.

This was agreed upon, and it was also decided to dispense with the 'normal' Owen Williams split faced blocks which were standard for facing abutment walls, to allow them to be poured in one lift to rocker or bearing level.

Re-use of formwork was planned so as to reduce costs, but with hindsight it might have been better to go for adjacent bridges in parallel rather than in series, which blocked the carriageway for twice the time. This was especially relevant to the A57 interchange bridges, both being of heavy rocker support type, which also featured a cantilevered footway/duct bay on each side which could not be started until the in situ deck had been fully stripped out and deflected under its own weight.

The service area at Woodall consisted of earthworks, drainage, footbridge, retaining wall and car parking.

Drainage for the M18 was difficult, involving excavating sixty miles of drain trench 8 in. wide by 1 ft. deep to 4 ft. 6 in. wide and 10 ft. deep in solid rock.

The opening ceremony was performed by Mr Stephen Swingler, MP, Minister of State, in November 1967.

This interchange between the A1(M) and the M18 was designed by West Riding engineers and constructed as an advanced contract to make possible the interchange between the Doncaster By-pass A1(M) and the M18.

The contract was let to Dowsett Engineering Construction Ltd in mid-July 1965 for the sum of £169,000. The work involved the building of four bridges as part of the roundabout over the Doncaster By-pass; two bridges over the A1(M) and two to the west allowing a minor road, White Cross Lane, to pass beneath the roundabout. Completion of the White Cross Lane bridges was required within 10 months and the two A1(M) bridges within 12 months.

The White Cross Lane bridge decks were single spans having prestressed pre-cast beams with concrete infill. The drawing showed stainless steel dowels 20in. long and 1¾in. dia. in the fixed end bearing shelf at 24in. spacing.

The construction of the two bridges over the Doncaster By-pass entailed Dowsett's having possession of the north and southbound carriageways for six weeks each.