This length of the M18 from Doncaster By-pass to Thorne was divided into the following contracts

This length of the M18 from Doncaster By-pass to Thorne was divided into the following contracts:

Wadworth Viaduct Wadworth to Armthorpe Armthorpe to Hatfield Hatfield to Thorne (Thorne By-pass) Thorne to East Cowick The contracts were carried out over a period of six years from 1970 to 1978 by the North Eastern Road Construction Unit and the West Riding and West Yorkshire Sub-Units.

The contract covered road and bridgeworks which extended the existing Northern to Wadworth section of the M18 across the A1(M) Doncaster By-pass to link with the Wadworth to Armthorpe section of the M18.

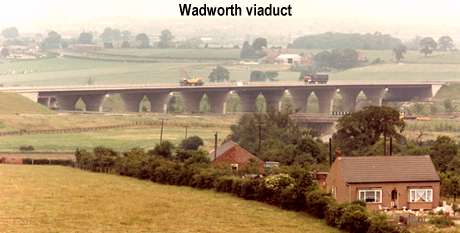

Wadworth Viaduct carries the M18 over the A1(M) interchange roundabout, White Cross Lane and the A1(M). The viaduct has seven 39.25 metre spans and there is a longitudinal joint between the carriageways. The deck for each carriageway is constructed of 6 longitudinal steel plate girders acting compositely with a reinforced concrete deck slab.

The longitudinal connections between the plate girders were originally designed as plated, with friction grip bolts. However, an alternative proposal by the steel-work subcontractors for site welded connections was accepted. The girders were fabricated in approximately 20m sections and welded on site to form a continuous construction.

Generally two beam sections were welded together on the ground to give a lifting length of 39.25m., which were lifted into place in pairs for stability during erection. Air welds were made at the quarter points of each span (with the exception of the first span) so that the lifted in length comprised of ¾ of one span plus ¼ of the next.

For the first span the beams were lifted in 50m lengths to form the first span plus ¼ of the next. To keep within the load carrying capacity of the cranes on site, these beams were lifted in singly, with stability provided by temporary bow strings to the top flanges.

Each deck is supported by reinforced concrete abutments and six pairs of reinforced concrete piers, each pier is tapered and widens out at the top to form a crosshead. All piers and abutments are supported on steel H-piles, with an average length of 12m, driven down into the Middle Permian Marl, except for the south abutment where the piles were driven on to a limestone layer. Steel H-piles were selected because of the aggressive ground conditions, with sulphate concentrations up to class 5. This rendered the use of concrete piles impracticable, and necessitated the waterproofing of the pier and abutment bases, in addition to the use of sulphate resisting cement.

Roadworks entailed the construction of approximately 250 metres of motorway connecting the completed section of the M18 from the west with the viaduct together with its surfacing. The motorway has an overall width of 17.6 metres consisting of dual carriageways each 7.3 metres wide incorporating 0.7 metres wide hard strips. There are two outside margins each 4.8 metres wide consisting of a 3.3 metre wide hardshoulder including a marginal strip and a 1.5 metre verge.

The carriageways were constructed of approved flexible materials comprising sub-base, road base and a flexible surfacing of two courses having a minimum final thickness of 100mm which extended over the viaduct.

The contract was for the construction, 12.0km of two lane Motorway connecting the M18 / A1 Interchange with West Moor Interchange Armthorpe then under construction. Five diversions of side roads and several diversions of farm access roads were constructed as part of the scheme, together with ten bridges, two underpasses and a number of other structures mainly for drainage.

The contract for the scheme was won by Dowsett Engineering Construction Ltd., in a Tender Sum of £9.54 million. The contract commenced in December 1976 and was completed in February 1979.

The southern end of the Works included two 15 metre rock cuttings and three areas of fill one being 15 metres high on the approach to the A1 / M18 Interchange and the other two approximately 10 - 12 metres high over the East Coast London Edinburgh Main Line and a Mineral Railway Line. The northern 4.5 kilometres is in shallow cut or fill in generally flat terrain.

The earthworks were considerable with approximately 1.6 million cu. m of cut and a similar amount of fill. However, nearly 300,000 cu. m of excavation was unsuitable material about 35% coming from the Loversall Carr area. The deficit of suitable material was made up with colliery shale from Rossington Colliery. About 1.5km from the M18 / A1 Interchange is Loversall Cutting in limestone, which was used below embankment for the rock blanket specified for 3.5km of the contract. At the Loversall Carr area roughly in the centre of the Works high approach embankments carried the Loversall Carr Railway Bridge over the East Coast Railway Line. These overlie an area of peat, alluvial and laminated clays. The peat and alluvial clays were excavated and the rest of the rock from the Loversall Cutting used as replacement. The East Coast Main Line created a major barrier for the earthworks operation and was overcome with the use of a 4 span Bailey Bridge of 100m over the railway. Approximately 1 kilometre north of this area is the other major cutting in Bunter Sandstone. Whilst excavated as rock the material was only suitable as a general fill. This source of material was used to complete all areas of fill north of the cutting and in addition provide fill for much of the southern end moved via the Bailey Bridge. Completion of the embankments of the southern 5km was made with colliery shale. Because of anticipated settlements the Loversall Carr Approach Embankments were instrumented and staged construction employed at both railway crossings.

There are 4 standard two span bridges and a further 3 standard 4 span bridges carrying side roads and farm access tracks over the Motorway. In addition there is a single span piled bridge carrying the Motorway over the Mineral Railway, a four span structure carrying the A638 over the Motorway, and Loversall Carr Railway Bridge. The latter structure costing approximately£1.25 million is of interest because of the need to produce negligible settlement of the East Coast Main Line. Because of the 40 metre depth of the peat and soft clays in the area it was impractical to found the structures on piles. Two central piers are designed with hollow polystyrene filled bases. The resultant loading on the two piers being equal to the weight of the material being excavated. Consequently in the immediate vicinity of the railways tracks the loading should be no greater than prior to construction. The ends of the structure rest on bankseats on the approach embankments. The archive contains a paper by Ken Hunt on the use of compensated foundations for the Loversall Carr Bridge129.

The A638 was a particular problem in that a perfectly straight road crosses over a 15 metre cutting on the alignment of the original road. The situation was further aggravated by the number of services in the A638 verges. As it was desirable to build the bridge on the line of the A638 a temporary diversion on a 15 metre high bund had to be constructed to allow excavation of the bridge site. Consequently all the services had to be temporarily diverted and on completion of the bridge diverted back into the bridge. Not more than 300 metres from this area is Hatchell Wood Railway Bridge. As the Motorway is in a 15 metre cutting it passes beneath a local railway line already in the cutting. The contract for this was let and supervised by British Rail. Prior to excavation beneath the line a bridge deck with lines in situ was placed upon cast in situ bored piles, involving closure of the line for 24 hours. Upon excavation the piles were faced with concrete to give a final appearance as conventional bridge piers and abutments.

Some 47 kilometres of piped drainage along with 10 kilometres of open ditch was employed in draining the Motorway and intercepted existing land drainage. In addition 2 pumping station contracts were let by the local Drainage Boards to facilitate outfalls.

The pavement was of flexible construction made up of 40mm wearing course, 120mm basecourse and 210mm lean mix concrete roadbase with variable thicknesses of sub-base dependant on the bearing capacity of the formation.

In order to construct the works a total of 94 hectares was required although not all this land was taken permanently. The final works are bounded by 27 kilometres of fencing.

Statutory undertakes works involved the diversion of 9 medium and high voltage overhead YEB supplies and several underground diversions, four high pressure gas main diversions, one being a twin 24 in. national gas grid main, protection measures to existing sleeved mains and several low pressure diversions, one major and three minor Post Office Telephone diversions, two major and three minor Water Supply diversions and minor diversions of foul and surface water sewers.

This contract covers the construction of about 6.0km of motorway between a point 1.5km to the east of Armthorpe and the southern end of the existing section of M18, Thorne By-pass, 1km to the north east of Hatfield.

In addition, a link road for traffic from the east side of Doncaster was constructed from the railway bridge at Edenthorpe to an interchange at the southern end of the new section of motorway.

Diversions to six existing roads, the construction of six structures and the excavation for a new service area at Hatfield completed the works.

The Contractor for the scheme was A Monk & Co. Ltd. and the value of the tender was £4.72 million and commenced on the 12th December 1975 and was completed on the 27th July 1977.

The overall width of the motorway is 28.2m made up of dual two lane carriageways 7.3m wide, hardshoulders 3.3m wide, a 4m wide central reserve and verge of 1.5m wide.

A 2.5km length of the motorway in the middle of the contract was constructed over poor ground consisting of about 1m of soft clay containing lenses of silt and decomposed vegetation overlying sand. To overcome the problem of instability resulting from this clay, a half metre thickness of rock was placed directly on existing topsoil, prior to the construction of the remainder of the embankment.

The fill requirement for the scheme amounted to 550,000 cu. m., almost all of which came from the excavation for Hatfield Service Area, which, for environmental reasons was constructed about 3.0 m below existing ground level and further screened by 2.0m high top soil bunds around its perimeter.

Drainage through the low lying area was a particular problem. Run-off from the carriageway is collected in specially designed trapezoidal section concrete drainage channels, set at the back of the hardshoulder, which discharge at regular intervals into large drainage ditches excavated alongside the motorway embankment. The gradients of these stretches are very flat and flow depends entirely on the hydraulic gradient of the water in the ditches.

Water drained from the motorway, with the exception of a small quantity outfalling into a stream at Edenthorpe, passes into the man-made drainage system of the area at West Moor Drain and Woodhouse Sewer, both these large ditches passing under the motorway in large 2.0m culverts. To cater for the more rapid run-off from paved surfaces. Woodhouse Sewer was deepened and widened and a new pumping station constructed at Waterton Farm.

A flexible carriageway construction consisting of 300mm of sub-base, 210mm of lean concrete road base, 140mm of asphalt basecourse and 40mm of hot rolled asphalt wearing course was used.

3330 metres of side road diversions were constructed under the contract. These included the re-alignment of Holme Wood Lane an unclassified County Road, the diversion of Waterton Lane a private access road over the motorway, re-alignment over the motorway of Moss Croft Lane C252 and the A18 Trunk Road, together with re-alignment of Thorne New Road A1146 as a temporary connection with the existing Hatfield to Thorne Section of M18, and the construction of 1100 metres of a new unclassified County Road - Carr Side Lane.

Bridgeworks included West Moor North and South overbridge carrying the West Moor North Link to interchange with the M18. These have two simply supported spans, decks of M-beam and slab construction. Moss Cross lane overbridge is of similar construction having a skew of 27 degrees.

Waterton Lane overbridge has four simply supported spans, having box beams decks with an in situ concrete slab connecting them.

The above bridges were expected to be subject to mining movements in the future.

Epworth Road overbridge has two spans and an M-beam deck but is curved in plan. Epworth Road Services culvert carries a foul sewer, water and G.P.O. services beneath the M18 on the line of the existing A18. The culvert is of reinforced concrete box construction.

Mere Lane Pedestrian Subway crosses the West moor Link and is of in situ reinforced concrete box construction. As the subway could be liable to flooding two automatic self starting electric pumps are provided in a sump at one end.

Hatfield Service Area Subway under the M18 provides access to the Service Centre.

This contract was awarded to Sir Alfred McAlpine & Sons in the tender sum of £4.798 million and work started on the 1st September 1970.

This 3.6 mile section of M18 which was opened to traffic in June 1972 runs from a point on the Hatfield - Thorne Road A1146 to join the A614 at Waterside to the N W of Thorne. The Tudworth link is approximately one mile in length stretching east from the two level motorway interchange at North Ings to a point near Tudworth Hall Corner.

Approximately 2 million cu. yds. of fill material were imported and included unburnt colliery shale from Hatfield tip near Thorne and bunter sandstone.

This contract was awarded to Sir Alfred McAlpine & Sons in the tender sum of £4.798 million and work started on the 1st September 1970.

This 3.6 mile section of M18 which was opened to traffic in June 1972 runs from a point on the Hatfield - Thorne Road A1146 to join the A614 at Waterside to the N W of Thorne. The Tudworth link is approximately one mile in length stretching east from the two level motorway interchange at North Ings to a point near Tudworth Hall Corner.

Approximately 2 million cu. yds. of fill material were imported and included unburnt colliery shale from Hatfield tip near Thorne and bunter sandstone.

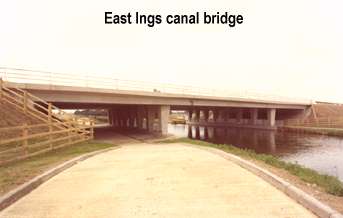

Of the 14 structures on the contract the major one is the East Ings Canal Bridge which carries the motorway over the Stainforth - Keadby Canal. The bridge has three spans , an overall length of 242 ft. with two piers founded on piles and the bank seats on embankment filling. Approximately 175,000 cu. yds. of peat (with bog oak) located on each side of the canal had to be excavated up to a depth of 20 ft. prior to commencing filling.

54RB Draglines were used standing on timber mats to spread the load. Material was passed from machine to machine until firm ground was reached. The work involved the prior protection of the canal banks with sheet piling, in order to avoid the possibility of draining several miles of canal. Unfortunately the piling did not toe into the underlying Bunter Sandstone, and so led to the removal of all the peat from under the south bridge abutment and to the need to jack up the bridge deck later in the contract.

Strain gauges were installed on the H-piles to establish loading conditions, and laboratory tests carried out to determine the Young's modulus for the imported Bunter Sandstone, colliery shale and fly ash and predict settlement.

The motorway construction programme has resulted in a large increase in the number of medium span bridges. Indeed, the 500th bridge to be built in the West Riding of Yorkshire since the beginning of the motorway programme is now in the planning stage. The design of the substructures associated with these bridges is usually based on lateral earth pressures calculated using the classical earth pressure theory originally proposed by Coulomb in 1776, and many of them take the form of abutments having cantilever wing walls.

In 1966 the West Riding County Council acting with the then Ministry of Transport initiated some tests into the earth pressures acting on the retaining walls.

The earth pressures acting on the four abutments of the North Ings Interchange bridges on the M18 motorway have been measured, together with the earth pressure acting on a cantilevered wing wall. Different backfilling materials have been studied. The results of the investigation compare favourably with the results of a three-dimensional finite element analysis which is considered to represent a more valid design approach."

This contract connected the M62 Pollington - Rawcliffe Interchange and the Dutch River to the Hatfield - Thorne (M18) section which had already been completed and opened.

The contract, which included the completion of the 2 level interchange at Waterside, was awarded to W & C French in the sum of £2.46 million. Having also won the Pollington - Rawcliffe contract on the M62, French combined both the jobs under the same site team.

Work on both contracts started on the 7th May 1973, this contract being completed on the 17th June 1975, some three months ahead of that on the M62.