At the outset of the investigation it was considered that the minimum survey information necessary to locate the motorway successfully would be up-to-date 25 in to 1mile plans, with contours at 5 ft intervals, as suitable Ordnance maps were not available it was decided that the quickest accurate method would be to undertake this work by an aerial survey. With Ministry of Transport approval this work was put in hand in December 1961.

In order to limit the areas for full aerial survey a model to a scale of 6in to 1mile, with 2 to 1 vertical exaggeration was constructed from the available Ordnance Survey detail. This enabled an appreciation to be readily made of the routes, which were to be investigated more fully.

As the choice of lines was narrowed down by design criteria and other considerations, planning restrictions previously imposed on building development were lifted on the routes which had been eliminated, and the 'zones' of restrictions reduced to the minimum necessary.

More detailed information was required on present and future traffic patterns and in June 1960 an origin and destination survey, with 27 survey points forming a number of screen lines, was carried out.

From this survey and more localised surveys from the County Boroughs of Huddersfield, Bradford, Halifax and Leeds the traffic needs of the West Riding conurbation were assessed.

Considerable problems were presented in the routing and design of the Pennine Section of the motorway by features of geology, geography and climate.

The weather in the Pennines provides hazardous conditions for the motorist with ice and snow in the winter. Fog, poor visibility, torrential rain and gales are also common throughout the year. It was obviously of great importance to minimise the effect of these hazards by careful selection of the route. A network of ten weather stations was set up in January 1962 along the alternative 'high' and 'low' level routes to provide comparative recordings of temperature, visibility and snowfall. From the data obtained it was estimated that the higher route would have 30 to 40 percent more fog; a 10 percent greater frequency of frost and 20 percent more significant snow. For these reasons the low level route was adopted.

This route crossed the county boundary at Windy Hill at a level of 1220 feet, quickly falling to 850 feet before crossing the Dean Head Valley to join a common route at Pole Moor. Through the Heavy Woollen Area between Brighouse and Morley a northern route was chosen of the two investigated.

Through the mining area between Lofthouse and the Great North Road the route to Selby Fork was found not to be practical and that to Ferrybridge was selected.

The problems of crossing the Pennines were unique and further specialised studies were undertaken after consultation with the Ministry and the Road Research Laboratory.

Investigations were also made into the existing use of land which showed the overall location of mining, other industry, and agriculture. Consultations with the County Mining Engineer gave information on subsidence in the area of motorway and on the general geology. This was further supplemented by a preliminary soil survey with trial boreholes along the alternative lines of the motorway.

The Pennine crossing posed major structural engineering problems and special studies were made into tunnels and ventilation, two level structures, canopies and road heating.

Construction of two trial embankments was undertaken in the autumn of 1962 using low cost materials, fly-ash, shale and a skimming of fine cold asphalt as a surfacing. Each embankment, of ranging heights and side slopes, was 100 yards long and to full motorway width.

A full time observer took daily measurements of snow depths and to record drift patterns. Continuous recordings were made at the site of temperature and wind speed and direction.

The results of these trials showed that side slope was more critical than height and that a slope of 1 in 5 was found to be the critical slope where snow was swept away. When roads in the locality were experiencing drifts of 8-12 feet the trial embankments were generally blown clear.

Two very deep cuttings at Windy Hill and Dean Head up to 150 feet deep required careful consideration and arrangements were made with the National Physical Laboratory to undertake wind tunnel tests.

The simple conclusion drawn was that in deep cuttings, space was the key factor. As a consequence the width of formation was increased for storage of prolonged snow, and to avoid avalanche conditions, side slopes no steeper than 1 in 1, with berms for increased storage were adopted. It was also found that at cut fill lines snow fences should be erected.

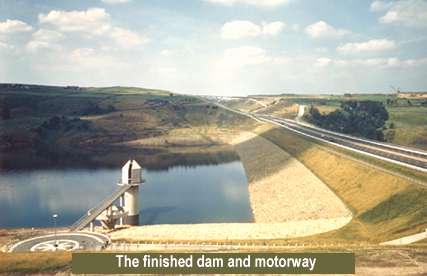

Coincidentally, Huddersfield Water Undertaking had been seeking to build a dam in this locality for some time, to supplement the Booth Wood reservoir. It was suggested that consideration should be given to using a high motorway embankment as an impounding dam. Huddersfield had engaged A.H. Waters and Partners as Consultants, with Professor Nash as geology specialist, and some fascinating technical meetings took place.

At this early stage both authorities saw the advantages of a joint scheme and a sound working partnership was founded.

In a co-operative exercise that is unique to this country, and possibly in the world, many legal, political and administrative, as well as engineering problems had to be overcome.

Having reached an initial agreement on a combined dam and motorway embankment each authority then progressed with its own planning - the Corporation with detailed design of a comprehensive water supply scheme, including tunnels, treatment works, pumping stations, catchwaters and aqueducts; and the County Council with the motorway. For design and supervision of the dam the Corporation appointed Rofe, Kennard and Lapworth as their consulting engineers.

This was the first time that a dam has been designed to carry a motorway on its crest and inevitably a number of novel problems had to be solved. On the legal side, Huddersfield Corporation had to promote a private Bill in Parliament to obtain the necessary powers for the work, which were eventually granted in the Huddersfield Corporation Act 1965. No less a problem was the sharing of costs between the water and motorway authorities. Then because safety was paramount the Minister appointed the Corporation as his agents for the section of motorway across the dam together with full and complete responsibility for all aspects of the structure. In addition, it was necessary to acquire several farms.

At this stage the basic design had proceeded to the stage where centreline levels had been established to achieve an approximate balance in mass haul quantities. It had been calculated that about seven million cubic yards of rock - mainly Kinderscout Grit - would need to be excavated over the length, the most spectacular section of earthworks being at Dean Head and Scammonden where the road would need to pass from cutting about 150 feet deep to cross a steep-sided valley on embankment 200 feet high or thereabouts. The main difficulty to be overcome was that while highway engineers were seeking a stable embankment in which adequate compaction to avoid settlement was combined with free-draining characteristics, the Water Authority's target was a water-tight (earth) structure incorporating clay core, sealed foundations, armoured (rip-rap) face, and so on.

Added to this conundrum there was the whole question of how to excavate 7 million cu. yds. of rock and place it in embankment in a reasonable time at a reasonable cost. There were many characteristics of the Kinderscout and other local gritstones with which the engineers were not familiar within this context and they would be literally breaking new ground. It became clear that fairly large scale field trials needed to be undertaken, in which the Water Authority and their Consultants would be invited to participate. A site at Dean Head was chosen (where some preliminary snow accumulation measurements had already been undertaken), and a contract let to John Laing, primarily on a Dayworks Basis, in the sum of £150,000.

Site offices were set up at Dean Head that Spring of 1964 and the whole of the summer months devoted to the tasks of establishing:-

I.C.I. Explosives Division gave advice on drilling pattern and depth, amount of explosive per hole and stemming details. They were told the overall objective and they provided a recipe for the Contractor, who duly complied.

The result was far from satisfactory, producing large gritstone lumps - which were simply not suitable for a motorway embankment. The West Riding engineers decided to proceed on their own. They persevered in our search for the optimum combination, attracting the interest of civil engineers from far and wide with their pioneering efforts.

By July they had sufficient information to be able to advise the design team of the practical time scale for incorporation of the earthworks element in the overall programme for the whole 39 miles of the M62 under design, which they were anxious to complete and present to the County Council and to the Ministry of Transport. It was decided that the earthworks from the Lancashire boundary to Pole Moor (6 miles) could be realistically undertaken from April 1966 to September 1968, primarily in the two summers of 1966 and 1967, given reasonable weather. This would lead to an overall target completion date of June 1970, and a detailed programme for the various sections of the motorway was formulated on this basis.

The trials continued, both to fine tune the blasting and excavation details and to produce a method specification, which it was now quite evident would be more practicable than any required density end product specification. Various types and combinations of compaction equipment were tried on different layer depths, the assessment of results by digging trial pits, with attendant sampling and density testing being particularly tedious. Further sampling and laboratory testing were also undertaken to meet Professor Nash's strict control requirements for dam construction.

Much effort was put into harmonising the objectives in this respect, till the fairly obvious compromise was reached, the design of the dam would incorporate a thick layer of the clay to act as a seal on the upstream side, brought up with the embankment as tipping proceeded, the face to have rip-rap protection, the base to include a curtain wall and the sides benched in with additional clay sealing.

The rock trials were not the only experimental work undertaken on the top of the Pennines that summer. One of the things we needed to know for fence design was just how high your average hill sheep could jump, since the prospect of mobile mutton meandering across the Motorway was not a happy one. Estimates varied, even from experienced hill farmers. Finally, one of their number offered to help us mount a practical test. He had some ewes in season which he put into a sheep pen, accessible by barrier of adjustable height, his prize ram on the outside. This noble animal finally cleared 5'6" in his eagerness to get to his harem. Very reluctant he was too, once having entered the sheep pen, to be forced to return outside to have another go as we gradually raised the barrier. Allowing for appropriate exhaustion factor, we concluded the design height for the motorway fence across the moors should be six feet. An environmentally-friendly type of fence to this height strung between slender pylons was duly selected.

Following the detailed investigations on the route, the draft section 11 Scheme for the length between the County Boundary and Outlane was published in October 1963 and the scheme made in October 1964 with the proviso that the Minister would consider objections between Pole Moor and Outlane when the draft scheme for the next length was considered.

The next length between Outlane and Lofthouse was published in February 1964. Objections were received and a Public Inquiry was held in County Hall on 25-27th May 1965, Sir Fredrick Armer KBE CB MC was the appointed Inspector.

Alternative lines put forward were investigated in detail and proved to be either more technically difficult or more costly.

Following a site visit and meeting with objectors the Inspector submitted his report and on the 3rd August 1965 the Minister made the scheme on the draft line. Some 18 months having lapsed between publication and making the scheme.

The draft Section 11 scheme between Sheffield - Leeds Motorway M1 at Lofthouse and the A1 at Ferrybridge has published in October 1965. Draft side road orders followed.

In time all tasks were completed, contracts prepared and tenders could be invited.

Eleven major contracts were required to take the M62 Motorway from Lancashire County boundary, in the West, to Ferrybridge Interchange on the A1 London-Edinburgh Trunk Road and then extend eastwards to Goole and subsequently to Hull.

Two lengths of Motorway connect the M62 to the major cities of Leeds and Bradford, the M621 and M606.

From the initial invitation to the West Riding County Council in January 1962 it was to take until May 1976 to complete the M62 and involved the North Eastern Road Construction Unit, the Sub-Units of the West Riding and Durham County Councils, and the consulting engineers, Scott Wilson Kirkpatrick & Partners.

The sketch plan below shows the sections described in the summaries of the M62, related to their current junction numbers. You may click on any section to bring up the appropriate page.

M62. Lancashire - Yorkshire Motorway

Statistics and options.

| Section | Construction started | Opened to traffic |

| Boundary to Pole Moor (J22 to West of J23) | October 1966 | October 1971 |

| Pole Moor to Outlane (J23) | June 1969 | November 1970 |

| Outlane to Ainley Top (J23 to J24) | June 1970 | 1972? |

| Ainley Top to Chain Bar (J24 to J26) | June 1970 | July 1972 |

| Chain Bar to Gildersome (J26 to J27) | June 1970 | May 1973 |

| Gildersome to Lofthouse (J27 to J29) | October 1968 | February 1971 |

| Lofthouse to Hopetown (J29 to J31) | March 1972 | August 1974 |

| Hopetown to Ferrybridge (J31 to J33) | March 1972 | March 1974 |

| Ferrybridge to Pollington (J33 to East of J34) | October 1972 | October 1974 |

| Pollington to Rawcliffe (East of J34 to J35) | April 1973 | June 1975? |

| Rawcliffe to Goole (J35 to J36) | ?1973 | March 1975 |

| The Ouse Bridge | January 1973 | May 1976 |

In both its design and construction this contract from the Lancashire County boundary to Pole Moor incorporating the Scammonden Dam, to carry the M62, the largest rockfill dam in the United Kingdom, was unique. It presented the West Riding Engineers and the contractors with the greatest of challenges in working under extreme climatic conditions and of overcoming unparalleled physical problems.

In motorway history it must rank as one of the great feats of engineering and worthy of a more detailed record than can be given here. A far more detailed account, particularly of the dam construction, can be found in the Executive Summary, details of which can be found in the pages "about the motorway archive".

Although having successfully tendered for the M1 contract outside Wakefield in consortium with Fairclough(AMEC), Sir Alfred McAlpine & Son Ltd had decided to 'go it alone' and were awarded the £10.5 million contract. It was the first motorway contract in this country to involve large-scale rock-shifting and, at that time, probably entailed the most impressive concentration of large excavators assembled on one project in the UK.

Where the M62 passes from Lancashire into Yorkshire the county boundary is marked by the Pennine Way footpath. The westernmost structure in the West Riding contract is the slender concrete arch that carries the ancient path over the six-lane motorway at a height of 65ft. At this point the M62 is at its highest elevation and deep in the Pennine hills. The next 7 miles, across the moors to the edge of Huddersfield, presented the motorway builders with their greatest challenges - five major rock cuttings, the removal of impassable peat bogs, a major dam, as well as some of the worst weather in the country.

Just east of the Windy Hill cutting the M62 crosses the Halifax-Oldham Road A672 at the Rockingstone Moss Interchange - the first on the Yorkshire side and the only one on the actual Pennine section.

Just east of the Windy Hill cutting the M62 crosses the Halifax-Oldham Road A672 at the Rockingstone Moss Interchange - the first on the Yorkshire side and the only one on the actual Pennine section.

This interchange is also used for access to the maintenance depot which was sited nearby, because the existing road is unfenced across the moors it was necessary to provide "cattle" grids to prevent the sheep, which freely graze on the moor, from wandering onto the motorway which is bounded by specially designed stock fences.

From Rockingstone the motorway strikes out across the high open peat-covered hills of Moss Moor, over 1,000 ft. above sea-level. Viewed from the side here the motorway can be seen as a series of embankments and cuttings levelling out the very irregular landscape it has to cross. And the embankments are built of the material excavated from the cuttings.

Some 12 million cu. yds. of material, 8 million cu. yds. of it solid rock - had to be handled over nearly 7 miles of very inhospitable terrain to prepare the way for the carriageways which when built could be traversed in just under 6 minutes.

Because of the scarcity of solid stable features such as buildings to act as reference points for the original survey a comprehensive system of monuments had been positioned over the whole site by three-dimensional coordinates to an accuracy of less than one inch. These monuments were located in places unlikely to be disturbed by the construction and were used as bases from which to set out accurately the construction of the motorway.

Access to the parts of the site where the contractor wanted to start working was the major headache. On Moss Moor the first job was the removal of some 650,000 cu. yds. of peat on the line of the motorway. The average depth of peat was 5ft. but pockets of up to 20 ft. depth were met and this sort of terrain presented a major obstacle to the job of simply getting about the site. Once the vegetation was stripped from the surface of the moor the peat had virtually no bearing weight capacity and could hardly support the weight of a man. Conventional vehicles, even tracklayers, simply could not negotiate it.

After coming close to losing a couple of excavators to the bog the contractor eventually evolved a satisfactory method for digging out the peat. This involved cutting straight through it and running the plant and equipment on the underlying, more solid strata, then excavating the peat from the exposed vertical face."

The peat itself had no agricultural, horticultural or other commercial value and was stacked in specially selected disposal areas on the hillsides adjacent to the Motorway and later landscaped to blend in with the surrounding countryside. It was so glutinous that dump-trucks with heated bodies had to be used to ensure a clean discharge and thus a full payload each trip. After lime fertilising and seeding the only way the disposal sites can now be identified is from an aircraft.

The motorway dam was the biggest single job and its rate of progress determined the time of completion for the whole scheme, therefore access to the dam area was a first priority. To operate vehicles and heavy plant into and out of the steep sided valley, over 400 ft. deep, haul roads were built which zig-zagged down the hillside with a maximum gradient of 1 in 5.

McAlpine's earthworks required a major investment in heavy excavation plant of £3,500,000, the key items of which were three 150RB 6 yd. face shovels, three 110RB's (4½ yd.), three 71RB's (3½ yd.) and fifty 30 ton, 35 ton and 45 ton rear dump trucks made by GM, Aveling-Barford, Caterpillar and International.

The main cuttings and the quantities yielded were Windy Hill 120 ft. deep, 2,500 ft. long, 1.2 million cu. yd., Deanhead 150 ft. deep, 2,600 ft. long, 4.65 million cu. yd., Croft House 90 ft. deep, 1,700 ft. long, 1.3 million cu. yd. and Wholestone 50 ft. deep, 5,000 ft. long, 1.2 million cu. yd. The material from Windy Hill formed the embankment over Moss Moor. Most of the material from Deanhead went eastwards to form Scammonden embankment/dam, as did Low Platt, Croft House and Wholestone cuttings.

Scammonden embankment/dam is 240 ft. high, 2,100ft. long, 1,220 ft. wide between toes, and consists of some 4.5 million cu. yd. of rockfill, in addition to the filter material and clay core. During the winter of 1968/69 some 52,000 tons of clay from Dowsett's Gildersome - Lofthouse Contract was transported to Scammonden and used in the construction of the Dam.

The optimum quantity of rock to be blasted out in any single operation was up to 40,000 tons. Rockfill was compacted by large vibrating rollers, the largest of which, weighing 11½ tons dead weight, were developed on site specially for the contract. The micro delay blasting techniques and borehole patterns established in the trials which produced the maximum fragmentation with little need for secondary treatment proved to be very successful on the actual contract.

For two of the three summers worked on this contract the Pennines were lashed by some of the heaviest rains on record, with 66 in. falling during the first year twice the national average - and as much as 4 in. in 2 days on at least one occasion. Moreover the cloud here is often down to around 1,000 ft. and much of the site was frequently lost in cloud which at times reduced visibility almost to nil.

This amount of rainfall, over the large areas of the motorway site, amounts to a huge volume of water. Really effective drainage was one of the main priorities of the contract, not only for the carriageways themselves but also for all the surrounding hillsides. Carriageway drainage is by continuous channels built into the marginal haunch and covered with pre-cast slotted concrete slabs. At intervals the channels are intercepted by catchpits from which water is piped into adjacent streams and ditches. Where the motorway embankments have to be protected from heavy run-off from the hillsides paved cut-off ditches have been built which channel the water under the carriageways via culverts.

These moors are a major water catchment area for the Wakefield and District Water Board and it was necessary to ensure minimal interference with the existing catchwater system during construction of the motorway. Running the full length of Moss Moor and Moselden Pasture is an open catchwater which is crossed by the M62 in two places, once on embankment and once in cutting. In the cutting, at Deanhead, the catchment water is taken under the motorway through an inverted syphon consisting of twin prestressed concrete pipes, 3 ft. in diameter, tested to a head of 200 ft.

On the embankment, in the middle of the Moss Moor stretch, the building of the motorway caused a constriction in the catchwater. This made necessary the construction of a further outflow weir and spillway just upstream of the crossing. At times of heavy rain the weirs discharge water from the catchwater into the adjacent valley, which already contains a reservoir, so that it is retained in the Wakefield collecting system.

The extrusion machines used to lay the marginal haunch and the drainage channel were also improved by the manufacturer in the course of this contract. The carriageway sub-base was spread and laid to a fine tolerance by a Rahco finishing machine handling 2,000 tons of material a day. Levels and tolerances were automatically set by the machine using information fed back through a feeler in contact with a preset wire.

Because of the low ph value of the moorland, water special protective treatments were given to steel corrugated culverts and steel mesh boundary fencing. High strength dense concrete and air entrainment were used in drainage works and structural concrete in contact with the ground protected with a bitumen treatment.

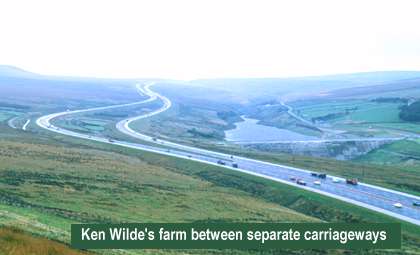

The moorland stretch of the M62 was built on geologically creeping side long ground and each embankment had to be anchored and benched into the underlying sandstone base. This called for separation of the carriageways over three-quarters of a mile which fortuitously enabled Wildes farm and buildings to be retained together with several acres of rough grazing. Access tunnels were provided under each carriageway for maintenance of the Water Authority catchwater, which also provided access to the farm.

It was also the first use of a tensioned wire barrier in the central reserve to avoid snow build up. The embankments which were aerodynamically designed to minimise snow deposits already referred to and the motorway has never closed due to driven snow in the 29 years it has been in operation. It was closed once through industrial action when salting and gritting was not carried out.

The motorway carriageway construction consists of 7 in. of imported type 1 sub-base, a 7 in. asphalt base and 4 in. of two course rolled asphalt surfacings.

There are eleven structures on the contract. The Pennine Way Footbridge which carries the 250 mile Pennine Way footpath across the motorway. The bridge consists of a reinforced concrete three pin arch of 220 ft. span with side cantilevers. Each cantilever supports prestressed concrete approach spans each 85 ft. long.

Rockingstone Interchange Underbridge which carries the motorway over the Halifax - Oldham Road A672. This skew bridge has two spans having a deck of pretensioned pre-cast concrete 'I' beams with an in situ concrete slab supported on reinforced concrete abutments and a central pier.

Scammonden Bridge which spans the Deadhead cutting carries the former A6025 Elland - Buckstone County Road over the motorway. Although originally designed as a flat arch spanning the cutting, further consideration of the aero dynamic and vibration characteristics of the bridge led to a redesign, an important consideration being to minimise disturbances in the air flow through the cutting which would cause snow drifting.

Because the site afforded excellent foundation material, it was decided to build an open spandrel fixed-arch bridge.

The final design of the arch was arrived at as the result of a series of computer programmes and proved to be both aesthetically pleasing and economic. It has a span of 410 ft. supporting eight spandrel walls which, with four further walls on the cutting sides under the approach spans, carry a deck 660 ft. long, 120 ft. above the motorway.

All the 18 in. thick spandrel walls have concrete hinges at the top and the shorter ones also have hinges at the bottom; those over 20 feet tall are flexible enough to accommodate thermal and other movements of the deck. The deck is composed of standard M.O.T. inverted T-type pretensioned prestressed beams with in situ concrete infill. The arch which is of twin box section is the largest of its type in the country.

Hey Lane Underbridge carries the Motorway over a district road. Redlane Dyke Bridge is a four span steel box girder bridge over the motorway and required additional stiffening under the Merrison rules. There are also seven reinforced concrete underpasses for agricultural and Water Board use.

It was during the building of Scammonden Bridge that the effects of an exceptionally severe Pennine winter were experienced. The centering of the arch was a conventional scaffolding structure of gigantic proportions. It contained no less than 70 miles of scaffolding tube. And it had to be designed for wind speeds of up to 110 miles an hour. In the sub-zero conditions that prevailed during much of the construction period the worst hazard of all was freezing fog. This left a build up of ice on everything in its path and created unprecedented structural problems as well as almost impossible working conditions. During the first winter the ice build-up was so heavy that the scaffolding framework had an additional load on it estimated at over 1,100 tons.

This type of ice build-up also brought down a nearby television mast, as well as telephone and power cables, and cut off the construction site from the outside world. The site offices were left without heat or light; emergency generators were not powerful enough to combat the intense cold and the offices had to be abandoned. Construction plant and equipment, too, was brought to a standstill.

The building of this bridge gave rise to special problems because rock had to be blasted from the cutting whilst concreting of the arch was continuing. We cast samples of concrete on a trial scaffolding and monitored the effects of vibration from blast effects. The results first of all confirmed our specifications to be a practical one showing that blasting could be carried out close to the structure without impairing its integrity.

An unusual detail of the centering was the anchorage of the thrust rakers to the rock using epoxy resin bonded rag bolts in order that they could cater for both tension and compression.

In addition to the suite of computer programs to aid the engineers designing the arch, another was written to analyse the effects of various construction sequences for the spandrel walls and deck so that the Contractor's proposals could be quickly checked to guard against overstressing the structure during construction.

As the M62 passes under Scammonden Bridge and out of the eastern end of the Deanhead cutting it starts out across the 2,000 ft. rim of Scammonden Dam.

To prevent high sided vehicles from being blown over as they emerged from the shelter of the cutting onto this exposed embankment, the ends of the cutting slopes had to be very carefully arranged. The profile of the motorway on the dam itself was also subjected to rigorous design studies and these led to the provision of simple but effective wind-breaks in the form of slatted fencing on either side, below the level of the carriageways.

From Scammonden the road continues its descent towards the next interchange at Outlane, the last structure on this Pennine section of the M62 built under the adjacent contract.

As with all schemes landscaping was an important consideration and the ledges in the deep cuttings now have flora and fauna of their own.

A major project like the Scammonden Dam changes the whole face of the valley. Huddersfield corporation were conscious of this and were anxious not only that the engineering works should fit well into their background but also that the completed reservoir area should be a source of pleasure and recreation to the whole district. Trees were planted and picnic areas laid out, with parking and other facilities, a sailing club formed and the land immediately around the reservoir used for stock farming.

Through extreme weather it became necessary to extend the contract period leading to completion in 1971.

On Thursday 14th October of that year Her Majesty the Queen inaugurated the Lancashire - Yorkshire Motorway, a historic day for all those involved and said :

"I am very glad to be here this afternoon to commemorate the completion of the Scammonden Dam and Reservoir. To construct a dam on this scale is a fine achievement; to build a motorway across it at the same time is remarkable.

It is and outstanding feat of engineering and also an excellent example of effective partnership between central and local government.

I congratulate all those who have worked so hard to bring this outstanding project to a successful conclusion."

Another plaque was erected on the county boundary, Lovell and Drake had wanted their county boundary signs to be erected but this was not permitted. However, a concrete plinth made with Pennine aggregates embossed with the Lancashire and Yorkshire red and white rosettes was erected and stands to this day.

The final cost of the entire scheme which included additional contracts awarded to McAlpine was £13.98 million - the most expensive rural stretch of motorway in the United Kingdom.

M62. Lancashire - Yorkshire Motorway

Statistics and options.

| Section | Construction started | Opened to traffic |

| Boundary to Pole Moor (J22 to West of J23) | October 1966 | October 1971 |

| Pole Moor to Outlane (J23) | June 1969 | November 1970 |

| Outlane to Ainley Top (J23 to J24) | June 1970 | 1972? |

| Ainley Top to Chain Bar (J24 to J26) | June 1970 | July 1972 |

| Chain Bar to Gildersome (J26 to J27) | June 1970 | May 1973 |

| Gildersome to Lofthouse (J27 to J29) | October 1968 | February 1971 |

| Lofthouse to Hopetown (J29 to J31) | March 1972 | August 1974 |

| Hopetown to Ferrybridge (J31 to J33) | March 1972 | March 1974 |

| Ferrybridge to Pollington (J33 to East of J34) | October 1972 | October 1974 |

| Pollington to Rawcliffe (East of J34 to J35) | April 1973 | June 1975? |

| Rawcliffe to Goole (J35 to J36) | ?1973 | March 1975 |

| The Ouse Bridge | January 1973 | May 1976 |