The Market Town of Penrith and the City of Carlisle had long been in need of relief from traffic congestion. Apart from the effect of local traffic movement, they both lay at the junction of major traffic routes. The most important factor, however, was the influence of the London-Carlisle-Glasgow-Inverness Trunk Road A6 passing through the centre of the two urban areas.

In particular, Penrith suffered from the effect of what was known as 'Arnison's narrows', a single lane section of the A6 controlled by traffic lights. A similar constriction existed in the village of Eamont Bridge.

A report was prepared as long ago as 1930 on behalf of the Cumberland and Westmorland County Councils, and the Penrith Urban District Council, which considered eight proposals for by-passing Penrith. However, it was not until July 1962, when through traffic volumes had reached 25000 vehicles per day, that the Ministry of Transport invited Cumberland County Council, as the Agent Authority, to carry out surveys and prepare a scheme. Fourteen different possible routes were considered before the chosen route was finally selected.

The southern starting point of the By-pass at Hackthorpe, where a temporary junction with the A6 was to be built, was determined by the Ministry in conjunction with Scott & Wilson Kirkpatrick & Partners, who had been appointed for the design of the motorway through Westmorland. The topography did not favour a route to the east of the town and it was considered that a western by-pass would provide better opportunities for east-west connections.

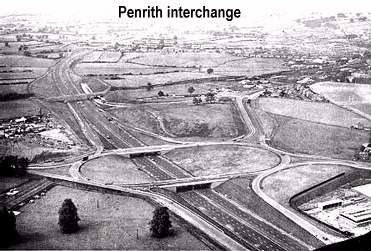

Approximately halfway along the eight mile length of dual three-lane motorway, and close to the Town, it was proposed that a two-level interchange should be constructed connecting the A66 Trunk Road to the motorway. From the interchange, major works were to be carried out on the A66 route, involving the construction of 2 miles of new dual two-lane carriageway in each direction, westwards towards Keswick and Workington, and eastwards towards Scotch Corner and Middlesborough.

A further two-level interchange was provided as a northern terminal at Catterlen, including the link road connections eastwards to the A6, and westwards to the B5305, the route to Wigton.

At public meetings, where the proposals were described, the benefits to the Town Centre which the motorway would bring, were recognised. More detailed discussions took place with major landowners which proved to be particularly fruitful. The Lonsdale Estate was affected over the major part of the route and was prepared to consider modifying farm boundaries in such a way that there would be a reduction in the extent to which tenancies would be split by the motorway, thereby reducing the number of accommodation bridges.

In the design, a great deal of care was taken to ensure that the effect on the environment was reduced to the minimum by, ensuring that:

* the horizontal and vertical alignments were coordinated to avoid optical kinks

* earthworks were rounded, and landscaped by making use of surplus materials

* deep cuttings were taken out on a curve to avoid interference with the skyline and

* a visibility envelope was prepared to examine the effect of the motorway on the adjoining land, and vice versa.

The statutory procedures were completed without significant problems.

The Contract for the construction of the motorway was awarded by Cumberland County Council with a starting date of the 1 November 1966 and a period for completion of 27 months.

From the site investigations which had been carried out it was found that boulder clay was the predominant soil type. In some instances the boulders were of considerable size, i.e. at least 12" in diameter. Full scale trials had been undertaken before the award of the Contract, the information having been made available to all tenderers. Because of its sand and silt content, the clay was very moisture susceptible. The materials of higher moisture and sand content were easily distinguished and were classed as unsuitable for use in embankment construction. The specification stated that after the formation was trimmed to level it was to be covered with a polythene layer on which was to be placed two inches of sand. The Type I sub-base was then to be laid on the sand. It was questionable whether this nominal layer of sand would protect the polythene from damage by the sub-base material or from the plant used in its placing and compaction. The sand also dried out and tended to blow away!

This specification was tried on Mayburgh side road and on the main motorway cuttings south of Clifton. Two things became apparent:

* The polythene membrane prevented the escape of moisture and led to dramatic softening of the top layers of the clay matrix

* In the trimming process, boulders that protruded above formation level were being plucked out, with shavings of clay filling the resulting interstices. These pockets could not be compacted. The hollows attracted moisture, which softened the adjacent clay.

The Contractor suggested that a better solution would be to place a layer of granular material on the clay formations which would prevent capillary rise and provide a stable foundation for the sub-base. This detail had been used successfully on earlier sections of the M6 where it was described as a rock layer (subsequently this would become, in the standard design, an SF1 layer providing a working platform on which the pavement could be laid). Instructions were issued to provide this granular fill to act as a capping layer.

This instruction was a major change to the contract as the contractor had made no provision for any granular borrow pits. Indeed granular material in that area was difficult to find unless of course crushed limestone was used from quarries which were already over-stretched. However, the contractor was fortunate enough to locate sandstone pits at Cliburn, which served the south end of the contract and another at Bow Scar serving the northern end. Both pits were situated on routes not able to be used by motorway traffic. Instructions were issued to strengthen these local roads and the pits provided this entire additional fill. Whilst these sources resolved the immediate problem, the materials were not ideal because although they were certainly granular, they unfortunately contained a much higher proportion of fines than the more openly graded bunter sandstones of Cheshire and Lancashire.

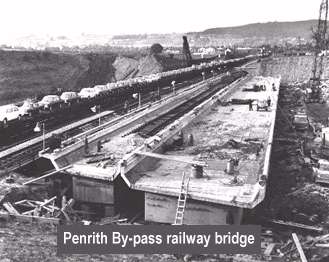

In all, 22 bridges were required. Three were designed by British Rail to carry the West Coast Main Line railway over the motorway and the new westerly section of the A66. The superstructures were of post-tensioned in-situ concrete, each built alongside the railway track and traversed into position using closed circuit television as a means of controlling the operation.

A variety of differing types of design were used for the other bridges, the most unusual being the Lowther Bridge. The substructure consists of four reinforced concrete skew arch ribs springing from bearings on thrust blocks founded on rock. A cast in-situ reinforced concrete slab deck is carried on two spans of Preflex beams.

In general, piled foundations were not necessary. In recognition of the location of the By-pass, on the fringe of the Lake District, masonry facing was used on thirteen of the bridges, with the majority in natural stone.

Earthworks started early in February 1967, and although the bulk of the operation was carried out before the end of September, a wet October prevented its completion as programmed. Abnormal weather conditions were experienced in March 1968, which caused further delay, and highlighted the need for additional river protection at bridge sites.

The works were completed three months ahead of schedule and the By-pass was opened to traffic on 7 November 1968.