Thelwall Viaduct is 4,414 feet long and rises to a height of 93 feet above the Ship Canal. It was of sufficient width to accommodate dual three-lane carriageways and a central reservation but, in order to reduce the cost of the structure, hard shoulders were not provided. This proved to be the cause of accidents when vehicular breakdowns blocked the running lanes and a source of serious traffic problems when lanes were closed during maintenance operations.

Ground conditions were particularly difficult, with soft alluvial deposits over the whole of the site. The land between the canal and the river had been used for the disposal of canal dredgings and was overlaid by a layer of silt some 45 feet deep. In consequence, the reinforced concrete piers, which varied in height from thirty to eighty feet, had to be carried on piles up to 130 feet in length, to provide a satisfactory foundation. The superstructure consists of steel plate girders supporting a reinforced concrete slab deck. The erection of the girders in the 336-foot main span across the canal had to be undertaken without affecting shipping, which included ocean-going vessels of up to 12,000 tons and the Contractors completed this difficult operation by cantilevering the girders from each side of the crossing.

The main works, which included a further 79 bridges of various designs, began in February 1961.

Early site investigations had identified a wide variety of soil conditions, with clays of varying plasticity, soft and hard grey shales, dry and very wet sands, peat, sandstone and even coal, all of which required different forms of treatment.

For 13 miles, the motorway passed through mining areas and in several places the seams were exposed during construction. Some 13,000 tons of good quality coal were excavated and handed over to the National Coal Board, which had rights of ownership. Unrecorded shallow mine-workings were also found and, depending on their depth, were either back-filled or protected by reinforced concrete slabs, as were many old mine shafts, some up to 900 feet deep.

Future subsidence was expected over a length of almost ten miles and the carriageways, drainage systems and eight bridges were designed to cater for up to 13 feet of settlement.

A feature of the southern part of this section of motorway was the presence of bunter sandstone. In many of the cuttings it was encountered during excavation and, not only did it provide an excellent formation, but the material taken out was used both in the construction of embankments and as a sub-base for the carriageways. Additional material of this type was obtained by the Contractor from a major borrow pit alongside the motorway, thereby reducing the amount of construction traffic on the local road network if other sources had been used.

In contrast to the Preston and Lancaster By-passes, a stronger form of carriageway construction was adopted with, in general, a base of 6½ inches of cement-bound granular material overlaid with 3½ inches of dense bitumen-bound macadam. However, in the areas likely to be affected by subsidence, the bitumen-bound material was used for the full depth, to give greater flexibility.

Apart from the interchanges at the ends of this section, ie immediately north of Thelwall Viaduct and at Bamber Bridge south of Preston, there are seven other junctions with the existing road system of which three required the construction of substantial link roads. Whereas the all-purposes Winwick Link joined the A49 to serve the northern part of Warrington, the motorway-standard South Link and a new section of road at Shevington, north of the town, provided Wigan with full access to the motorway.

The first motorway Service Area in the North West was developed at Charnock Richard between Wigan and Preston. From the experience gained in the operation of Service Areas elsewhere in the Country, improved facilities within a better planned layout were introduced.

Whereas progress on both the Preston and Lancaster By-passes had been seriously affected by long periods of heavy rainfall, the memorable freeze-up early in 1963 brought work to a halt for a period of eight weeks. However, due to the considerable efforts of the Contractors, this section of motorway was completed by the Summer.

The motorway was already under construction through Cheshire and, in order to ensure that the traffic problems of Warrington would be relieved as soon as possible, arrangements had been made for the early completion of a 1½ mile section from the A50 at Lymm to the southern end of the Thelwall Viaduct.

The whole length between the A50 and Preston was, therefore, opened to traffic in July 1963 with Thelwall Viaduct the longest motorway bridge in use in Britain at that time.

By the early 1980's, a serious situation had developed along the 6 miles of the M6 between the junction of the M56 and the M62. This heavily trafficked section of motorway had to cater for, not only North/South movement between the West Midlands, the North West, and Scotland, but also for East/West traffic between the Merseyside and Manchester conurbations, wishing to cross the Manchester Ship Canal. With traffic flows regularly up to 140,000 vehicles per day, the dual three-lane carriageways were frequently subject to queues and delays. The comparatively steep approaches to Thelwall Viaduct, and the absence of hard shoulders on the structure, added to the capacity problem.

Furthermore, inspections of the Viaduct showed that the deck was suffering from severe chloride contamination brought about by the effects of de-icing salt.

Pell Frischmann Consultants Ltd were appointed by the Department of Transport to carry out a feasibility study into the options for increasing capacity on the section between the two junctions, and to consider the form of treatment necessary to renovate the deck of the Viaduct.

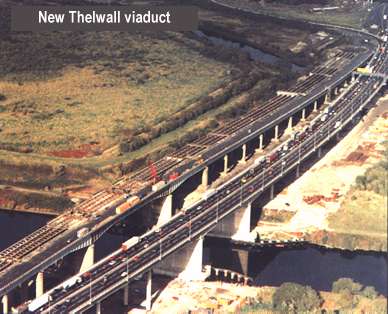

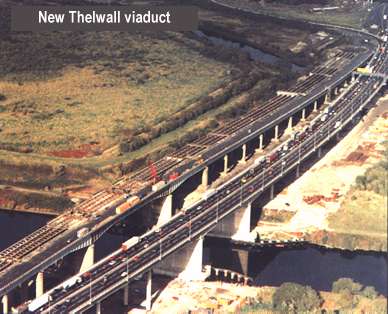

Both on-line, and off-line widenings to the east and west of the existing motorway, were investigated. The scheme which provided for upgrading to dual four-lane carriageways, including the construction of a new Viaduct on the east side of the existing, was the subject of a Public Inquiry held in May 1990 and the statutory procedures were completed in August of that year. Following detailed design, tenders were invited and work on the construction of the second Viaduct began in January 1993.

The new Viaduct, the centrepiece of the widening scheme, accounted for almost half the scheme's cost. The structure, designed to complement its 30 year old neighbour, was commended by the Royal Fine Arts Commission for embracing advances made in bridge design and construction technology since the early 1960s. The new structure has integral cross-heads and a totally continuous welded plate girder deck which, at 4500 feet in length, is the longest such structure in the world. The majority of the twenty-six 170 feet long, spans are 1½ times the length of those in the original structure, yet the deck girders are only marginally greater in depth. The piers consist of pairs of 7 feet diameter columns, except at the canal span where solid leaf piers provide the fixity for the deck. All the foundations are piled, the piles being an average 80 feet in length providing a mixture of end bearing into gravels and skin friction into clay. The deck is fixed to the pier nearest its centre point and each end can move by up to 24 inches due to expansion and contraction between temperature extremes. This movement was a major consideration in the design, requiring particular attention during construction, when movement of up to 4 inches per day had to be accommodated.

In recognising the importance of future maintenance, the design included the provision of an access walkway beneath the full length of the Viaduct, with transverse walkways at the mid-point of each span. The spans over water were to be decked out completely.

Traffic management was paramount to the project's overall planning and design.

The programme required the construction of the new Viaduct, with conventional widening of the existing section of motorway to dual four-lane standards. The new Viaduct would temporarily carry all the motorway traffic, whilst the original Viaduct was being renovated under a separate contract. In April 1995 the first lane of traffic used the new Viaduct and, in the following month it became fully operational, by carrying three lanes in each direction.

The renovation contract included the complete demolition and reconstruction of the concrete deck; work on the substructures; modifications to the steelwork to reduce the number of expansion joints; the replacement of all bearings; and the installation of maintenance access facilities. The Contractor made the important decision at the outset that all the structural steelwork would remain in place, and that the renovation would be carried out 'half at a time', to enable longitudinal access to be available at deck level, at all times.

Apart from the work on the Viaducts, the scheme entailed the demolition of 14 bridges, sign gantries and retaining walls, and the construction of five overbridges and five underbridges, together with other major works.

The renovated Viaduct was opened to traffic in December 1996, thereby enabling dual four-lane carriageways, with hard shoulders, to be brought into use throughout the whole of the section between the two junctions.