Background

The M6 Toll motorway dates back to the early 1980s, when the UK Government identified a need for a scheme to relieve the heavily-congested M6 through the West Midlands conurbation, which, from its opening in 1972, was heavily congested. By 1980, peak flows of 130 000 vehicles a day - almost twice its design capacity - made it one of the most heavily-used motorways in Europe. Early suggestions to widen it were quickly dismissed as unrealistic, and after public consultation, the decision was taken to build a new motorway north-east of Birmingham.

Consultations on several route options for what is now officially the M6 Toll road (working title: Birmingham Northern Relief Road or BNRR) culminated in a preferred route announcement by the Secretary of State for Transport in March 1986, followed two years later by a public inquiry.

In May 1989, before the inquiry outcome was announced, the Government decided that, in line with its new policy objectives, the BNRR was to be procured at no cost to the public purse, and introduced a private sector competition to design, build, finance, and operate the new route. Two years of legal challenges followed. Trafalgar House and their successors Kvaener had fallen by the wayside. Midland Expressway Ltd (MEL) was now owned 75% by McQuarie of Australia and 25% by Autostrada the Italian state-owned motorway operator. In 2000, six years after the start of the repeat public inquiry, all the legal challenges were cleared and MEL invited tenders from contractors. In the event only two groups tendered; CAMBBA and Bouyges/Skanska. The winners were CAMBBA, a consortium of Carillion, McAlpine, Balfour Beatty and Amec. Ove Arup and Partners, who were MEL's original design consultants then, together with W. S. Atkins. became the design consultants to CAMBBA except for the toll collection system and its hardware. MEL appointed Babtie to look after their interests during the construction stage and the Highways Agency retained the services of Owen Williams who had been the original consultants to the public sector scheme.

The Consultants' commission included a site-based team of around 30 people providing design support to the contractor during construction, and inspection of the works to ensure compliance with the design. The project included a challenging overall completion target of 173 weeks and several interim milestones were set, attracting bonuses if they were bettered and penalties if they were missed. The penalty for failing to achieve overall completion being approximately £170 000 per day. Needless to say, with such potentially large sums of money involved, the pressures on achieving the design and construction programmes were intense.

The backbone of the organisation was four highway design teams, each handling a section of the motorway corresponding to the sectional division used by the contractor for construction. Atkins designed the two northern sections in their offices in Birmingham and Epsom, while Arup designed the two southern sections, working from its Midlands Campus office at Solihull. The four sections are respectively:

1. 5.9km from the northernmost point (M6 Junction 11a) to M6 Toll Junction T7 at Bridgetown (Atkins)

2. 11.9km from Bridgetown, Junction T7, to Shenstone, Junction T5 (Atkins).

3. 15.3km from Shenstone, Junction T5, to M42 Junction 9 at Cudworth (Arup)

4. 10.4km from M42 Junction 9 to the road's southernmost point, where it links with the M6 Junction 4 (Arup).

Discipline co-ordinators (eg highways, drainage, geotechnics, structures, environment, building engineering, etc) operated project-wide across the four teams, ensuring uniformity in both technical and presentation standards and, in most instances, providing design services in their particular disciplines. Although the whole Arup/Atkins Joint Venture (AAJV) team came from the two firms, there was total integration and corporate boundaries never presented a problem.

Structures

The contract includes 57 new bridges, 7 interchanges and 6 toll stations. The extremely tight construction programme called for the first 19 steel overbridges and six concrete underbridges to be fully designed and issued for construction within the first eight months of the programme. The design objective was to provide aesthetically pleasing, open structures that were simple to build and replicate, thus achieving significant resource savings from development of the tender design. The aim was to ensure that the structures would be constructed without impacting on other activities.

The overbridges, therefore, followed the following build principles:

- twin main beam, two-span steel composite (or ladder beam) decks

- open-bank seat supports above artificially strengthened sideslopes in reinforced earth

- common elements such as piers and return wingwalls standardised

- skew taken out at the deck ends to simplify fabrication and connection detailing.

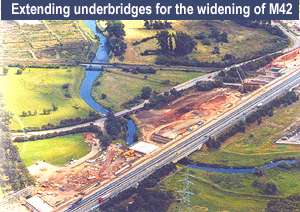

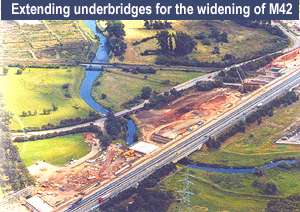

The structures programme also involved modifying some existing bridges, and during widening of the M42 to accommodate the new toll route, five existing underbridges were extended by approximately 30m. Existing structures required a full structural assessment in addition to the new design, and so needed considerably more resource effort than brand-new bridges. Key to design was the ability to ensure consistency and compatibility between the old and new.

Highways

Generally, the route follows existing major road corridors, thus minimising the effects on the wider landscape, and with alignments carefully developed to optimise the cut-and-fill requirements. Whilst much of the route was in cutting or on shallow embankments, the creation of mounds and false cuttings helped blend the road into the countryside. During the detailed design, the alignments were optimised further to win more locally occurring aggregates, which were used in the pavement and concrete structures.

The junction layouts at each end of the scheme were complicated by the concession agreement which made the M6 Toll the 'through route', so that traffic wishing to continue along the M6 had to exit the M6 Toll to rejoin the M6. This requirement both complicated the junction layouts and influenced the performance of the interchanges.

At the southern end, a major interchange between the M6 Toll, the M42, and the M6 extends over approximately 8km. This complex section was heavily constrained by existing motorway links, local roads, and structures that had to be retained, as well as rivers and railways, and the proximity of residential properties. To alleviate these constraints, the preferred design included a combination of parallel construction, asymmetrical widening, and symmetrical widening. The alignments were designed to reuse as much of the existing pavement as possible, whilst minimising overlay thicknesses and not imposing unacceptable additional loading to the existing structures.

Environment

Many measures were taken to mitigate the effects of the route on the local environment. Ecologists, a landscape architect, and environmental scientists were all involved at each stage of the scheme.

From the outset of construction, ecologists managed the clearance of site vegetation and helped in relocating significant flora and fauna. About 2ha of wet heathland was translocated to a carefully prepared receptor site - a double-lined lagoon, 1 .5m deep, and backfilled with carefully stratified selected materials. This created a soil profile to match the donor site. Specially designed machinery was introduced to allow giant 2.4m x 1.2m x 0.3m turves to be lifted and laid, accessing the site on temporary floating sleeper roads.

Approximately 1 ha of dry heathland was created through a combination of techniques, including prior harvesting of seed from a Site of Special Scientific Interest (SSSI) through which the motorway was being constructed. Heather turves and peaty topsoil were also recycled separately from this SSSI and respread on the motorway verge prior to seeding with the harvested seed. Elsewhere, heather brash harvested during management operations from a nearby country park was used to create new heathland on screening bunds.

A wide variety of wild fauna living on or frequenting the site, including white-clawed crayfish, newts, water voles, badgers, otters, bats, and Fallow and Muntjac deer, was relocated or otherwise protected as part of the works. Most of the roadway is fenced against various combinations of badger, otter, deer, and newts, and over 60 mammal passes and ledges have been provided in addition to road and pedestrian crossings, enabling animals to cross the motorway safely. Four otter holts, two badger setts, and hundreds of bat boxes were provided, along with numerous log piles for animal habitats.

It was imperative to maintain the rural landscape and feel of the region through which the route passed, and major shrubbery planting took place on and off the line of the motorway to help conceal and blend the scheme within the surrounding landscape. Approximately 1 M trees and shrubs were planted over two winters during the course of the works. Almost 130 offsite plots were planted through agreement with landowners. In addition, ornamental planting around toll plazas includes herbaceous flower and ground cover beds in an effort to introduce human scale and create a more convivial workplace environment for the toll station workers.

Drainage

As a separate entity to the drainage system, 20 ponds were created. This was primarily for ecological purposes though the largest is intended to be used as a commercial fishing lake. They have common features to increase ecological value; translocated and imported aquatic plants were used and several of these ponds were perched and required lining. In addition, 11 existing ponds were retained and modified to maintain ecological and amenity value.

Watercourses totalling 9.5km were diverted, incorporating meanders, riffle weirs, fluctuating bank gradient, depth and width, sandbanks, aquatic planting. A wide variety of erosion control methods were built in, including gabions, riprap, geotextiles, car rolls, live woven willow, and translocated rushes, in addition to in situ concrete.

At the motorway drainage outfalls, a total of 28 balancing ponds were built to limit or attenuate the discharge to adjacent watercourses. Each pond combines with an oil inceptor to provide pollution control.

Two-thirds of the ponds include further ecological mitigation features such as islands, static water areas separated from the main part of the pond, reed beds, and marginal/marsh planting shelves at various levels relative to normal water level, gravel beaches, and hibernacula (part-buried riprap hibernation areas). Where necessary, drainage channels were lined to protect aquifers.

Upstream of the ponds, the M6 Toll drainage combines kerbs, gullies and hollow kerbs; combined surface water and groundwater drains (filter drains); the longitudinal drainage channel (In the central reserve); and ditches.

The drainage is a gravity system, except for the outfall from the Shenstone cutting, west of Tamworth and south of Lichfield. Here, as it passes under the Sutton Coldfield to Lichfield railway,the M6 Toll is forced into a low point below the level of the nearest watercourse, Crane Brook, 500m south, and thus requires a pumped outfall. The gravity network outfalls into a wet well comprising a 12m diameter, 12m deep chamber formed of precast segmental concrete rings. Upstream of the wet well, only limited attenuation was possible and so to accommodate a 1:50-year storm, the well contains four pumps, each with a capacity of over 1100 litres/sec. Water is pumped to a header tank at the top of an adjacent earth mound, from where it flows down a 1350mm diameter gravity main to an attenuation pond prior to discharge into Crane Brook.

Geotechnics

Arup's geotechnics team applied a wide range of measures to enable reuse of materials. By processing site-won materials, pavement quality aggregate, concrete aggregate, drainage stone, building sand, selected granular materials, and cement bound material aggregates were produced for the project. This ensured a minimal import of materials and a largely balanced earthwork. Despite early concerns about the need for some 'selective' working to be done within glacial deposits, the use of motorised scrapers proved to be a great success, helped considerably by relatively good weather during the construction period.

The route crosses a variety of geological materials typical of the UK Midlands: the Sherwood Sandstone, Marcia Mudstone and Coal Measures strata. Overlying these strata, a variable thickness of superficial deposits relating to past glacial periods was present. Generally, ground conditions were good, but deep `sub-glacial' channels infilled by a variety of poorer materials were present in places In addition, 16 areas of potentially contaminated land had to be dealt with. Quantitative risk assessments were carried out on the contaminated materials and in general the team was able to prove that most of it could be reused within the works.

In a significant number of areas, reinforced soil abutments proved a more cost-effective solution than piling, particularly since the specified class of granular backfill to the reinforcing straps was site won. Elsewhere, both piled and conventional shallow foundation solutions were adopted.

Part of the route corridor had to contend with shallow mineworkings and deep backfilled opencast excavations. Again, a range of measures was required - including drilling and grouting, surcharging, and structural solutions - to deal with these issues.

Pavement design

MEL have a 53 year concession to operate the toll motorway. This had a significant bearing on the pavement design and construction. The team designed a range of pavement options for use at different locations, so as to suit existing ground conditions and traffic loadings, and provide the most cost-effective solutions. Two principal options were selected for the main carriageway: continuously-reinforced concrete pavement (CRCP) with thin wearing course overlay, and fully-flexible bituminous construction. As well as ground conditions, the choice of option was based to a large extent on the availability of site-won materials, and the variability in width of the carriageway.

It was fortunate that the route traverses a very large quantity of glacial sand and gravel that could be, and was, processed to form a substantial portion of the motorway pavement. Approximately 50% of the length is constructed in CRCP using site-won aggregates, including all of the concrete, the cement-bound material, and capping. The pavement construction platforms of subbase and capping material were made stronger than the standard design in order to cope with the heavy construction traffic loading and reduce the risk of a premature, construction traffic-induced failure.

A 'concrete train' was used for the concrete pavement, laying the full 14.3m carriageway width in a single pass. The reinforcement was fixed in position in advance of the concrete train by an innovative Australian method, used for the first time in the UK on this project; then the 220mm thick CRCP was overlaid with 35mm of thin wearing course to provide a quiet and smooth running surface.

The fully flexible pavement option was adopted for the M42 southern end, where modifications to existing carriageway of varying widths and depths were required, and at the northern end of the project where ground conditions were variable and generally much poorer. Conventional paving plant was used for laying the various pavement layers in single-lane widths.

Toll Plazas

The multidisciplinary team of architects and engineers designed a total of 28 buildings for eight different needs at six toll station sites. The aim was to satisfy the functional requirements with integrated designs that emphasise corporate styling and value for investment, as well as safety and security. Close working relationships with the tolling systems' commissioners and suppliers were essential to ensure that all technical systems and building services were fully co-ordinated and integrated

Conclusion

There is no doubt that the M6 Toll is one of the most exciting developments in British road transport for many years. Under the scrutiny of industry and the media, there were high expectations of its performance, and studies following the opening of the 44km route show that the toll has been welcomed by a diverse range of road users. In summer 2004 the concession company, MEL, reported that the road was used by an average of 55 000 vehicles per day - an increase of 80% since January 2004, the first full month of operation. A major milestone was reached in August 2004 when the 10Mth customer using the route was logged.

From the first recognition by government that the M6 through the midlands needed relief it will have taken 24 years for relief to be provided. It remains to be seen how effective it will be in relieving congestion. The concessionaires (MEL) have raised £600 million to finance the scheme. To repay the borrowing they have set tolls at £3 for a private car and £11 for a lorry. This toll applies to using all or part of the road. If successful M6 toll could signal the provision of further toll motorways or a catalyst to tolling the motorway network as a whole.

(most of the text and pictures on this page are from The Arup Journal of January 2005, which is deposited in the Midlands Archive).

|

Principal Quantities

|

|

Topsoil Strip

|

1,300,000 cubic metres

|

|

Excavation

|

9,200,000 cubic metres

|

|

Fill

|

7,500,000 cubic metres

|

|

Excavated material processed

(Drainage, pavement, concrete)

|

1,600,000 cubic metres

|

|

Structural Concrete

|

63,000 cubic metres

|

|

Steel Reinforcement

|

10,400 tonnes

|

|

Formwork

|

90,000 square metres

|

|

Reinforced Earth Panels

|

22,300 square metres

|

|

Structural Steel

|

9,613 tonnes

|

|

Road Construction:

Main Line

Interchanges

|

1,369,000 square metres

184,000 square metres

|

|

Side Roads

|

447,000 square metres

|

|

Blacktop

|

800,000 tonnes

|

|

Carrier Drains

|

139,000 metres

|

|

Fencing/Hedges/Noise Barrier

|

165,000 metres

|

|

Safety Fencing

|

130,000 metres

|

|

Landscape Planting

|

4,430,000 square metres

|

|

Structures

Existing Bridges (20)

|

Widened 8

Demolish 4

Change 8

|

|

New Bridges (57)

|

Overbridges 34

Underbridges 12

Footbridges 5

Rail Bridges 3

Link Bridges 3

|

|

Culverts

|

Watercourses 41

Toll Tunnels 6

|

|

Retaining Structures

|

Walls 7

Strengthened Earth 4

|

|

Sign Supports

|

Gantries 53

Variable Message Signs 4

|