Anyone who studies a road map of the Midlands would be excused from wondering why a short length of motorway running through the rural areas of Herefordshire, Gloucestershire and Worcestershire was ever required let alone built. Even today, over 40 years since it was opened, it remains a delight to drive on with comparatively little traffic using it.

Anyone who studies a road map of the Midlands would be excused from wondering why a short length of motorway running through the rural areas of Herefordshire, Gloucestershire and Worcestershire was ever required let alone built. Even today, over 40 years since it was opened, it remains a delight to drive on with comparatively little traffic using it. The reason for this lies behind a pre-war vision that there was a need to connect the steel manufacturing centres of South Wales with the metal bashing industries of Birmingham and the Black Country. After the war, the then County Surveyor of Worcestershire was keen to see a new major road built between Cardiff and Birmingham and with the counties of Herefordshire and Gloucestershire pushing for a link between A449 at Ross and the A38 North of Tewksbury, the M50/M5 was spawned.

In an endeavour to get things moving after the war, the three counties took on teams of civil engineers who were being de-mobilised from the army. Detailed survey, route location and earthworks design commenced. For design purposes the project, as it affected Worcestershire and Herefordshire was divided up as follows-

North - South (M5) Quinton (J3) - Lydiate Ash (J4) (not originally part of M50/M6 strategy)

North - South (M5) Lydiate Ash (J4) - Strensham (J8)

The northern limit of M5 in Worcestershire was at Quinton with the Southern limit at Twyning on the Gloucestershire border.

The Lydiate Ash to Quinton Motorway extended the existing M5 northward for a distance of six miles. At the Quinton interchange the Motorway is joined from the west by the Halesowen By-Pass Extension, and from the east by the Quinton Link Road.

The project was opened by the Minister of Transport, The Rt. Hon. Tom Fraser, M.P., on Friday, 19th November, 1965. This marked the completion by Worcestershire County Council, acting as Agents for the Minister of Transport, of some 45 miles of motorway and 15 miles of major feeders during the preceding eight years or so.

Tenders were invited for the construction of the scheme, which had dual two-lane carriageways, in the spring of 1963 and let to Tarmac Civil Engineering Ltd (now Carrilion Construction) in the sum of £4,343,547.

The new length was generally similar to the section of M.5 already built by the County Council between Strensham and Lydiate Ash, but certain modifications were incorporated. The effective total width was increased from 88 ft. to 105 ft. and, although the carriageway and central reservation widths were kept unchanged at 24 ft. and 13 ft., respectively, the hard shoulders and outer verges were widened to 10ft. each. The cutting and embankment slopes were slackened slightly to a maximum pitch of 2:1, and the drainage system was made more positive by the use of a continuous edging at the back of the hard shoulders, shedding rainwater to gulleys. The minimum road pavement thickness was increased from 18in to 20in.

A 10in composite road base, consisting of 7in of lean concrete and 3in of tar-bound granular materials was adopted. The road pavement was constructed without the use of preformed haunches, based on experience during the construction of the earlier length of M5, and of the subsequent initial maintenance problems on some sections, caused by shrinkage of the surfacing materials away from the preformed haunch, allowing water to enter until sealed off.

The construction of the Motorway involved the movement of 3,000,000 cubic yards of earth. The size of this task on six miles of road can be judged by comparison with the 4,000,000 cubic yards which had to be moved in building the 28-mile length of the existing M5. The earthmoving was sub-let by Tarmac Civil Engineering Ltd (now Carrilion Construction),to Dick Hampton (Earthmoving) Ltd., and at the peak of their task they employed 48 No. rubber-tyred and tractor-drawn scrapers on the site.

The deepest cutting on the Motorway is at Chapmans Hill, where the vertical depth is 80 ft., and the highest embankment occurs at Lyeclose, to a height of 60 ft.

The materials for the pavement construction were won locally. Aggregates for lean concrete, cement-bound granular sub-base material being quarried at Romsley. The cement-bound materials were manufactured in two mixers erected in the quarry; the mixed material was then delivered to the site of the works in sheeted lorries and placed by payers. Basalt aggregates from Rowley Regis were used in the hot rolled asphalt and tar-bound layers. Tarmac Roadstone Ltd., the Sub-contractors for the black-top work, manufactured these materials at Hailstone quarry, in a plant which was reserved solely for the Motorway works during their construction.

The omission of haunches in the construction of the composite pavement caused some initial problems in relation to level control, but these were soon overcome by the ingenuity and keenness of the Contractors. This design feature increased productivity in the pavement construction and gave the added advantage of free surface-water run-off at all pavement-laying stages.

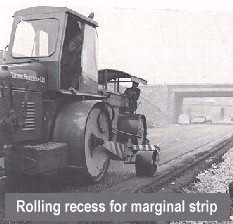

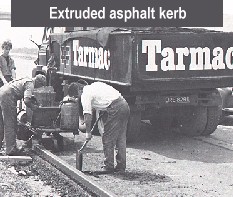

The laying of the final running-surface also brought some problems, particularly in making provision for the marginal strips. These were accommodated in the hot rolled asphalt wearing course by forming a ¼in recess for the calcined flint line below the top level of the final running surface. The ¼in. recess was preformed during the laying operations and the recess itself was consolidated by a small roller attached to a hydraulic arm on the normal compaction equipment. The asphalt kerb upstand at the back of the hard shoulder was extruded on to the final surface of the hard shoulder by special equipment.

The designs of the 19 bridges follow the pattern already established Extruded asphalt kerb on other motorways in Worcestershire, taking full advantage of modern design and construction techniques. In all nine of the overbridges, the central reservation pier was omitted, yet slender depth-span ratios maintained. The economic advantage of building these overbridges in reinforced concrete was known from earlier work in the County, so this form of construction was utilised wherever possible. Prefabricated prestressed concrete beams were incorporated in the suspended spans of five of the bridges, to avoid hindrance of the heavy earthworks by any need to erect staging across the carriageway lines.

The scale of the bulk earthmoving operations led to the selection of multi-plate Armco underpasses for four of the occupation crossings. The Armco structures were erected in areas of deep fill, and in some cases their length was as much as 250 ft. These were the largest underpasses of their type built in this country at the time and each was erected in about six weeks, fully justifying this choice of design.

As part of their motorway contract Tarmac Civil Engineering Ltd (now Carrilion Construction) built the access roads and parking areas at Frankley Service Area which overlooks the picturesque Romsley area, and is in two independent units, higher than the Motorway on the eastern side, and lower on the western side.

Within a few years of opening, congestion was occuring on this section, and it was widened. This is covered as a separate scheme.

The route of the first section of M5 to be published was in 1953 and was for the 28 mile section between Lydiate Ash and Brockeridge Common (A38) together with the M50 between Ross and Brockeridge (to be known as the Ross Spur). The only Public Inquiry was into the Ross Spur section. The other sections of M5 in Worcestershire were published in 1954, no further Public Inquiries were held.

The line orders were made in 1955. Draft side roads and Compulsory Purchase Orders were published in 1956. No Public Inquiries were held and the Orders made in 1957.

The section of M50 from Brockeridge Common to Strensham (M5) and the Strensham to Lydiate Ash sections of M5 were designed in detail between 1957 and 1959 and put out to tender in 1960 with work starting the same year. Some 28 miles of dual 2-lane motorway were therefore under construction at the same time. Due to the farmers' lobby, the road had an overall sub-standard boundary to boundary width of 88ft including 9ft hard shoulders. The standards at that time required an overall formation width of 105ft, although in the late 60's, this was reduced to 92ft.

For contract 1 (Brockeridge Common to Strensham) and contract 2 (Strensham to Lydiate Ash) alternative prices were sought for 18 month and 30 month construction periods. A Monk & Co submitted the lowest price for both contracts with an 18 month construction period. The contracts were let in March 1960, and opened to traffic on July 20 1962. It cost £250,000 per mile, exactly twice the cost of M50.

The Construction consisted of 6" to 18" stabilised sub-base (depending on CBR), 8" CBGB surfaced with 2½" HRA base course and a 1½" HRA wearing course with a high stone content. It has non-positive drainage. The only significant change in design was the removal of the channel block between the neaside edge of nearside lane and hard shoulder which was placed at the back of the hard shoulder.

The Strensham Service Area was built concurrently with this work.

The road was opened on 20 July 1962 by Lord Chesham.

The widening and reconstruction of this section is covered as a separate scheme.