The Water Orton Contract of the Tamworth Section of the M42 Birmingham-Nottingham Motorway is the lynch pin in the strategic route linking the M5 and M1 Motorways announced as long ago as 1968.

The Water Orton Contract of the Tamworth Section of the M42 Birmingham-Nottingham Motorway is the lynch pin in the strategic route linking the M5 and M1 Motorways announced as long ago as 1968. Following a Public Inquiry in 1972 the line order defining the Tamworth Section was made in September 1973. Suffering a long series of delays, the route was subjected to further Public Inquiries into Compulsory Purchase Orders in both 1976 and 1980, finally receiving approval in 1982.

Early stages of the design were undertaken by the Midland Road Construction Unit, but following the Unit's abolition in 1981, Ove Arup and Partners were invited by the Department of Transport to take over responsibility for the design and to carry out a review and updating of the projected scheme to match current practice. As a result of that review, significant changes to the design were recommended by the Consulting Engineer including the reduction of height to the main embankment by up to 3m, Following acceptance by the Department, Ove Arup and Partners were instructed to revise the design and prepare new contract drawings and documents.

Early stages of the design were undertaken by the Midland Road Construction Unit, but following the Unit's abolition in 1981, Ove Arup and Partners were invited by the Department of Transport to take over responsibility for the design and to carry out a review and updating of the projected scheme to match current practice. As a result of that review, significant changes to the design were recommended by the Consulting Engineer including the reduction of height to the main embankment by up to 3m, Following acceptance by the Department, Ove Arup and Partners were instructed to revise the design and prepare new contract drawings and documents.

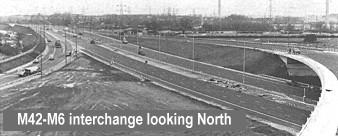

The Tamworth Section of the M42 runs to the North East of the City of Birmingham connecting with the M6 at a new interchange near Coleshill. The Section provides part of a new route from Birmingham to the North East superseding existing overloaded trunk roads. The Water Orton Contract completed the link with the Solihull Section of the M42. This dual three lane Motorway runs alongside the A446 Trunk Road crossing the flood plain of the River Tame adjacent to the notorious single lane section of the A446 near Water Orton and ends at a roundabout with the A446 and A4097 from where the Kingsbury Contract continues with only two lanes.

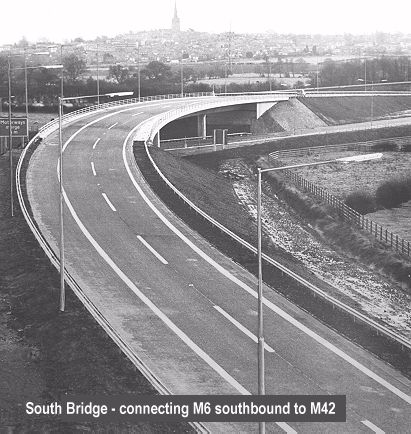

Link roads to motorway standard join the M42 to the existing M6 Motorway and form the 'cross-roads' of the Midland Motorway System.

Tenders were invited in November 1983 and Fairclough (AMEC) Civil Engineering Limited Northern Division were awarded the 120 week £22.9m Contract. Work commenced at the end of April 1984. They quickly produced a construction programme designed to achieve completion fully eight months early. Major sub-contracts were let for Earthmoving, Surfacing and Electrical work.

The construction works were supervised by Ove Arup and Partners, and materials testing was carried out by Harry Stanger Limited.

The Contract consists of 4.5km of Motorway, approximately 7.6km of Link Roads, 15 Bridges, 13 Overhead Gantries, a substantial embankment across the River Tame Flood Plain, a grade separated Interchange with the A446 Trunk Road and associated Side Road works.

Extensive advance works earlier carried out by the Department of Transport included junction improvements and the provision of temporary traffic signals on the A446.

Significantly, the large number of bridges in so short a route, allied to the design updating and reduction in height of the River Tame embankment resulted in all but four of the structures being completely re-designed by Ove Arup and Partners.

Unusual ground conditions encountered make the Earthworks particularly noteworthy. The geology of the area consists of a strong Keuper Marl Mudstone rock overlain by glacial deposits up to 30m thick. The glacial deposits are of two types; firstly the locally redeposited Keuper Marl and secondly Sand and Gravel. These are particularly significant in that they infill the channel of the ancient Proto-Tame Valley following the line of the Motorway and together with the alluvial deposits in the present River Tame Flood Plain provided considerable construction problems.

The glacial deposits are typical of the area being low in plasticity and of a variable nature, and this together with the high water table resulted in only 30% of the material excavated being suitable for re-use in the Works. The majority of this was only suitable for use in the construction of earthmounds outside the Motorway embankments resulting in 1,000,000 cu m of fill being imported to the site and in disposal of 250,000 cu m off the site.

The pavement materials selected by the Contractor was a composite construction of lean mix concrete and bituminous surfacing. The pavement consisted of 150mm of Type A Sub-base comprising type 1 crushed rock aggregate, 210mm of lean mix concrete, 100mm of DBM roadbase and 100mm of surfacing. The lean mix concrete was produced and laid on site by the Contractor using locally dug sand and gravel aggregates and the most modern Titan paver capable of laying the material to the full width of the carriageway in a single advancing face. The bituminous materials were supplied and laid by Tarmac Roadstone Limited.

For the capping layer under the pavement, designed to provide a stable all weather platform for road construction as well as increasing the pavement life, industrial waste materials were used to advantage. Originally the Contractor used well-burnt colliery shale from the abundant local tips but when the full reconstruction of a section of the M6 Motorway in Warwickshire commenced in summer 1985, excavated pavement materials, a mixture of concrete and bituminous material were imported to the site crushed in a mobile plant and placed on the embankments to form the capping layer.

A variety of structures have proved necessary to overcome both prevailing conditions and the road geometry. Apart from where the Link Road crosses the M6 Motorway, all structures consist of in-situ or pre-cast concrete construction, with the latter the most prominent.

The two elegant interchange bridges (North and South Bridges) benefited from such methods, assisting the Contractor to achieve his ambitious programme. Pre-cast 2.35m deck sections with in-situ concrete joints of varying width to create the deck curvature, allowed for rapid progress on these post-tensioned spine beam bridges.

Pre-cast M and U-beams were utilised for all motorway underbridges of which the four span 'viaduct' at Marsh Lane (Water Orton) is exceptional for an M-beam structure, spanning a railway line, side road and two open intermediate spans.

In-situ voided slabs and pre-cast M-beams were favoured equally for the four motorway side road overbridges.

All the pre-cast concrete beams were manufactured by the Fairclough (AMEC) Engineering Pre-Cast Division at Ranskill Nottinghamshire and Accrington Lancashire.

Where the Link Road crosses the M6 motorway. the road alignment was squeezed between the Chelmsley Wood Collector Road and the existing Motorway giving a maximum skew of 70° for the bridge. Because of the problems involved with building over the existing Motorway, a pre-formed deck was essential to enable erection of any bridge beams with minimum disruption to traffic. This resulted in the design of a deck consisting of 1.8m deep steel girders and an in-situ concrete slab on permanent formwork. This form of deck reduced the size of abutments and centre supports to the minimum. The plate girders were fabricated off site by Fairfield-Mabey in their Chepstow Works and lifted into position during two overnight possessions of the carriageways.

Where the Links cross each other for the interchange west bridge an in-situ. post-tensioned ribbed deck was utilised to reduce the construction thickness to a minimum. This form of construction presented the Contractor with many problems including the provision of formwork for the curved ribs which also splay at each end to the tensioning anchorages. The finished structure more than justified the efforts involved.

All of the structural concrete used in the Works was produced by a concrete batching plant, established on the site and manned by Fairclough (AMEC) staff to provide excellent quality control and workability of the concrete.

Simultaneous construction of all fifteen structures allowed for the opening date of Christmas 1985 to be met. To enable the programmed road construction to commence in late 1985, work continued throughout the previous winter.

Occupation of any existing Motorway is widely acknowledged as difficult but the West Midland section of the M6 is one of the most heavily trafficked sections of Motorway in the country with an average daily flow of 80,000 vehicles. In order to disrupt this traffic as little as possible during the major construction works special measures were necessary. Included in the Contract, therefore, were traffic signing and coning measures costing £½m to be executed by the Contractor.

The Contract provided for 13 different traffic arrangements carried out in six major stages to accommodate the Construction Works. In order to minimise disruption to traffic, maximum periods for each traffic arrangement were specified. It was a basic requirement of the Department of Transport that three lanes of traffic in each direction should be maintained at all times, (except overnight) and the traffic arrangements were designed to allow each stage of construction of the road and bridgeworks to meet this restriction.

Narrow lanes were specified for major construction phases and where no hard shoulder could be accommodated, recovery vehicles were provided by the Contractor. For the erection of the bridge superstructure and gantries, each carriageway was closed overnight by diverting traffic to the other carriageway on specially constructed centre-reserve crossings.

As a part of routine maintenance by the Highway Authority, it was recognised during the period of the main Works that strengthening of the existing M6 Motorway adjacent to the M42 Links would soon be required on the southbound carriageway and an extension to the Contract was awarded to Fairclough (AMEC) to carry out the necessary repairs in the area of the Links to a value of £890,000.

The extension included the replacement of the centre-reserve drainage, the removal of the existing bituminous pavement over the lean-mix concrete roadbase and the construction of a new bituminous upper pavement. The whole exercise including construction of temporary centre-reserve crossings, traffic control and the removal and re-erection of safety fence for the whole 1km length of the operation was completed in less than six weeks, thanks again to vigorous activity from the Contractor and the excellent teamwork displayed by all concerned.

A small rural community, Water Orton was surrounded in recent years by industrial development and the resulting expansion of the West Midlands conurbation. The close proximity of the new motorway to the villages of Water Orton and Curdworth demanded special consideration from the Department of Transport in assessing the impact of the proposed route. At a special environmental consultation in 1974, earth mounding and screens were introduced to the scheme to reduce the noise and visual effect of the Motorway on the adjacent properties.

During the redesign period, Ove Arup and Partners were able to assist in this objective by lowering the embankment near the village, thereby reducing its visual impact. The Contractor has also contributed to environmental improvement by using vast amounts of industrial waste material from spoil tips at the adjacent Hams Hall Power Station and from the long abandoned Piccadilly Coal Mine at Kingsbury to form the Motorway embankments. Fairclough (AMEC) has also used derelict areas near the Motorway to dispose of soil excavated in the Works but not suitable for re-use and thereby reclaim these areas for agriculture.

The scheme also includes large areas of landscape filling within the Motorway which together with the embankment and cutting slopes provide areas for the planting of 90,000 trees and shrubs which the Department of Transport plan over the next few years. Certain areas immediately adjacent to residential property are already in preparation for planting in the coming spring.

The construction of the Curdworth Roundabout and its associated side roads presented significant problems to the Contractor because of the multitude of Statutory Undertakers' mains and cables that lay beneath the existing roads. The phasing in of the service diversions, whilst maintaining traffic flow, required the implementation of complex planning arrangements to complete the new interchange. Consistently good co-operation was maintained throughout by all the parties involved, enabling completion in little over one year.

Throughout the construction period, special efforts were made to liaise with the local community to reduce the impact of the Works. This was achieved by a liaison committee in Water Orton with Parish, District and County Councillors and at Curdworth with the Parish Council.

The nearby activity of a motorway construction site aroused the interests of children aged 8 and below at Curdworth School and following a site inspection of the Works by the school the enthusiasm of the children and teachers was such that they undertook a major project on the Motorway involving all aspects of their school work. This involved visits to the school by the Resident Engineer to talk to the children about the building of the Motorway and to help the teachers relate this work to their children's own work at school. These young engineers responded so well to this exercise that the teachers expanded the project to involve the design of their own imaginary length of Motorway as a Spur from the new M42 into the village.

The children carried out a public opinion survey on their proposals, executed their own soil survey, designed the motorway, prepared drawings and documents and submitted them for tender to two Contractors. Fairclough (AMEC) again were successful but following the children's own Inquiry the proposal was rejected. When the Minister of Transport, the Rt. Hon. Mrs. Lynda Chalker MP, inspected the site in July 1986, she also visited the school and the children took great pride in the demonstration of their work.