This scheme involved the construction of 15.4km. of dual three lane motorway, three interchanges, thirteen bridges and the realignment of a number of side roads, two of which were each approximately 2.3km. long. The line of route runs just south of and roughly parallel to the A40 trunk road over its whole length.

From the interchange at Stokenchurch, the route runs westwards through the woodlands of the Chiltern Hills, a designated Area of Outstanding Natural Beauty. Over this length, the motorway is generally in cutting having a maximum depth of 47m where it crosses the escarpment. This cutting, which received careful consideration in order to minimise its effect on the landscape, is described in more detail later. Christmas Common Road runs along the crest of the escarpment and where it crosses the motorway it has been realigned to the east where the cutting was narrower and taken over the motorway via a 55m span overbridge.

The road descends the escarpment to an interchange with the B4009 which was diverted to by-pass the village of Lewknor. The difference in height of 120m between the top of the escarpment and Lewknor dictates a motorway gradient of 4% for more than 2000m. The embankment immediately west of the escarpment face is up to 17m high and is landscaped into the valley approach by filling the land adjacent to the road with surplus material from the deep cutting and unsuitable material from other locations on the contract.

Between Lewknor and Adwell the route runs in shallow cutting or on the low embankment and is screened by carefully preserved tree belts. Keeping close to the existing A40, the motorway is in cutting at Adwell and descends a small escarpment to the Oxford plain east of Tetsworth. Sweeping to the south of Tetsworth and on to Milton Common, the line and profile of the motorway was selected to minimise engineering difficulties with the Gault clay and to avoid intercepting the high water table in the Milton Common area.

At Milton Common, there is an interchange with the A329 and to the west, the road merges with the dual carriageway of the existing A40 trunk road.

From Stokenchurch to the escarpment edge, the route crosses the partly residual and partly Eocene deposited Clay-with-Flints. This is a firm to stiff silty clay with a very high flint content and forms a capping layer, varying in thickness between zero and 10m on the line of route, to the chalk of the Chiltern Hills. Large sandstone boulders (Sarsens), some estimated to weigh up to 50 tons, have been found within this layer.

All but the uppermost levels of the deep escarpment cutting are situated in the Upper Chalk strata. This is soft white chalk consisting of almost pure calcium carbonate, also with a high flint content, both randomly distributed and in bands. The chalk is highly fractured and fragmented and has a moisture content close to saturation.

Swallow holes caused by the solution of the Upper Chalk during periods of high-intensity rainfall have become filled with the overlying Clay-with-Flints to create the commonly occurring "pipes" in this area.

At the base of the deep cutting close to the face of the escarpment, the hard Chalk Rock band indicates the change to the Middle Chalk horizon. This is somewhat harder chalk with significant clay content and fewer flints than the Upper Chalk. Further to the west, the route crosses a low ridge along which the old pre-Roman Icknield Way runs and this marks the hard limestone Melbourne Rock interface between the Middle and Lower Chalk. The Lower Chalk is a hard poorly bedded chalk with no flints.

To the west of Lewknor, the chalk gives way to the Upper Greensand which in this area is a light grey siltstone, generally friable and thinly bedded but occasionally massive.

Proceeding towards Oxford, the ground surface falls rapidly just east of Tetsworth, due to the faster rate of erosion of the Gault clay which outcrops at this point. The Gault clay is a firm to stiff fissured blue-grey calcareous clay generally well over 40m thick. As a result of stress relief from the erosion of overlying strata and aggravated by glacial conditions, the Gault clay has developed extensive slip planes of very low shear strength. This phenomenon has been of paramount importance in the selection of the profile of the route in this area and in the design and construction of the embankments and cuttings.

At Milton Common, the ground surface again rises where the motorway crosses the plateau gravel. This consists of flint gravels with a proportion of fine sand and silt. The deposit is thin with a maximum thickness of 5m and overlays the impermeable Gault. As a consequence, the gravel is saturated with a mean water table level less than 1m below ground level. Glacial frost cracks occur throughout the outcrop and give rise to pockets of soft silt and sand.

A public enquiry into the route was held in April 1969 and following acceptance of the route by the Secretary of State for the Environment, detail design commenced in 1970. The Contract commenced on 13th March 1972 requiring construction to be completed in two years.

Features of the design of particular interest were:

1. Deep Cutting at the Escarpment

Very careful consideration has been given to the alignment of the motorway through the escarpment and to the shape of this cutting in order to minimise the effect on the skyline and to ensure the maximum integration of the road into the landscape. To test the stability of the cutting shape chosen and to establish its detailed form, a specialised soil survey was carried out in 1970. The survey called for a detailed study of the chalk by engineers and geologists who were lowered down large diameter boreholes to plot details of joints, fissures and faults and to obtain both disturbed and undisturbed chalk samples. By relating the properties of material in-situ to known conditions of failure, a stable cross-section was evolved. The Geotechnics Division of the Building Research Establishment was retained as Consultants to advise on the interpretation of the survey results. In order to provide an "early warning system" for possible slips, a stainless steel wire was strung between concrete columns constructed along the 6m wide berm. Monitoring of this wire to a fixed datum continued as excavation below the berm proceeded. At the foot of the steep face of the cutting, the verge was shaped and widened to accommodate minor falls of material. It also provides an overflow area for the soakaway drainage system.

2. Landscaped Areas

To the west of the escarpment, an integral part of the scheme was the filling of the combe on either side of the motorway embankment with surplus and unsuitable materials. Licences for these areas which amount to 25 acres were obtained by negotiation and the landscaping of them written into the Contract. As a result, the road which is, up to 17m above original ground level blends into the surrounding area and land that would otherwise form part of the motorway was returned to agriculture. In addition to the aesthetic benefit from this particular arrangement, a considerable economic benefit was obtained from the short-haul distance provided for surplus material from the escarpment cutting.

Additional finance was earmarked to cover extensive planting in both the deep cutting and the adjacent combe. Indigenous shrubs, trees and grasses were planted to bring the natural vegetation of the area as close to the road as possible. To this end, a large number of cuttings from the juniper, which grows wild in this area, have been taken for replanting on the southern upper slopes of the cutting. A considerable area of these upper slopes to the south of the motorway was to be leased to the Nature Conservancy for experimental studies.

3. Embankments on Gault Clay

The presence of slip planes in the Gault clay required special attention. In order to obtain an acceptable safety factor for stability, "toe trenches" were excavated 3m deep and up to 17m wide beneath the side slopes of all embankments on Gault clay and the side slopes flattened to 1:2½. The toe trenches were then backfilled with siltstone. Maximum use was made of the excavated Gault clay by varying the Specification to include material of higher plasticity and moisture content than normal. In order to prevent excessive pore water pressures In the embankments, a 500mm drainage blanket was provided over the area of the toe trenches.

4. Borrow Pits

The majority of excavation occurs on the eastern section of the route. In order to reduce haul distances, the Contractor obtained permission to work borrow pits on either side of the route in the Adwell area. These have been partly backfilled and landscaped with material unsuitable for forming embankments and enhances the visual attraction of the road as it passes through the siltstone cutting. It also reduces the return haul for the unsuitable material to the landscaped areas referred to in 2. However, an additional off-site tip was provided in the escarpment area by the Contractor to accommodate the increase in surplus material. The total amount of material excavated on the scheme was increased from approximately 3.5 million cubic metres to 4 million cubic metres as a result of these borrow operations.

5. Pavement Construction

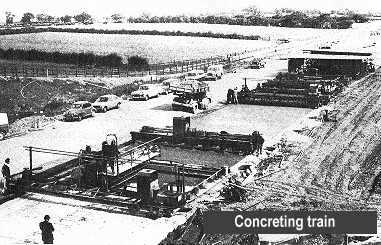

Like all major highway schemes, tenders were invited for alternative forms of both flexible and rigid construction. The cheapest proved to be for an unreinforced concrete pavement and the Contractor elected to use a conventional paving train. Two adjacent widths of pavement each 7.3m wide were laid to form one three-lane carriageway and hard shoulder, the width of 14.6m being constructed to the same depth and specification. Concrete at a high average output was required to complete the pavement within the short time programmed by the Contractor. A fleet of 18 side tipper lorries up to 7 cu m capacity ferried concrete from the batching plant at Lewknor. The concrete was laid in two layers approximately 230mm and 50mm thick. This enabled all dowel bars, both in transverse contraction and longitudinal joints, to be placed by vibration, no support cradles being used.

6. Silt Traps

In order to prevent possible pollution of watercourses, silt/pollution traps were provided on all outfalls to the drainage system and also to soakaways where the road crosses the chalk outcrop.

7. Deer Fencing

Although not often seen by the casual visitor, there are large numbers of deer roaming the wooded areas of the Chiltern Hills. To avoid the dangers that would arise to both the motorway traffic and the deer a 2.3m high strained wire deer fence was provided.

Of the 13 structures on this scheme, 5 of them were reinforced concrete box culvert underpasses. The remainder includes 2 three-span accommodation overbridges, 2 interchange overbridges, 2 side road underbridges, and 2 major arch bridges. One of the arch bridges carries Christmas Common Road over the motorway and the other carries the motorway over the B4009 at the Lewknor Interchange.

1. Accommodation Underpasses

Three of the underpasses were of standard DOE dimensions and two of rather smaller proportions, being required for pedestrian and equestrian traffic only. Reinforced concrete cantilever wing walls were provided on the approaches in each case. The box culvert design was chosen in view of the low bearing capacity of the Gault clay on which two of these structures were founded.

The two identical accommodation overbridges have main spans of 36m and side spans of 21 m. The decks, which were continuous over two piers, were of reinforced voided construction with curved soffits and coping lines. Each end of the bridge was simply supported on bank-seats which, like the piers, were on piled foundations.

2. Side Road Underbridges

The two single-span side road underbridges were of similar design. These structures consist of a reinforced concrete slab of skew span 10m simply supported on strutted abutments. The wing walls which have been provided with a fluted finish were of the vertical cantilever type. One of the underbridges is founded on Gault clay and bored pile foundations proved to be necessary.

3. Interchange Overbridges

At extreme ends of the scheme were situated the two interchange overbridges which were of similar design. However, the Three Pigeons Interchange Overbridge crosses the motorway on a considerable skew, whereas the Stokenchurch Interchange Overbridge is square.

These bridges were of the two-span type with a pier in the central reservation, the square width between abutment and pier is approximately 18m. The decks consist of standard precast, prestressed concrete beams with in-situ concrete infilling provided at top and bottom flange levels to form a cellular deck. The abutments and wing walls were of the reinforced vertical cantilever type and the piers have been designed as reinforced portal frames. The wing walls were parallel to the motorway so that they do not impair the sightline at the junction of the slip road and side road at the high level.

4. Lewknor Diversion Interchange Underbridge

An arch was chosen to carry the motorway over the Lewknor Diversion Road. This design, it was considered, would make the bridge unobtrusive in the rural environment given the steep grade of the motorway. There are no spandrel walls but the arch was shaped at each end so as to follow the plane of the embankment side slopes. The span of the reinforced concrete arch was 22m with a rise of 6m, the thickness varying from 600mm at the springings to 300mm at the crown. The mass concrete abutments were founded on the lower chalk and contain over 6000 cubic metres of concrete. Band-sawn Douglas fir was specified as lining to the intrados formwork in order to obtain a textured finish to the arch soffit.

5. Christmas Common Overbridge

The most interesting structure on the scheme is the Christmas Common Overbridge which carries the realigned Christmas Common Road over the motorway some 12m above carriageway level. The three pinned open-spandrel arch has a span of 66m between springings with a rise of 11 m and was 100 metres long. The side road is supported by means of the cantilever and suspended span with bank-seat type abutments, the entire construction being in reinforced concrete. The bridge was founded on the upper chalk, allowable bearing pressures being established by plate bearing tests as part of the pre-contract soil survey.

All piles on the scheme were of the bored and cast-in-situ type with a diameter of approximately 500mm varying between 6m and 15m in length. Most of the concrete used for piles was batched and mixed on-site while all other structural concrete was supplied from a batching plant some 10 miles from the site and delivered in truck mixers.

One of the features of the Contractor's method of construction was his extensive use of large, single panel shutters. The formwork consisted of a plywood lining with timber studding supported by vertical steel soldiers. Since cranes were required at each site to handle these large shutters, the main method of placing concrete was by crane and skip. However, concrete pumps were used on occasions when access or required rates of the pour, posed problems.

The falsework to the in-situ concrete slabs and arches consisted of heavy timber ribs supported by closely spaced scaffolding, the ribs being purpose shaped where necessary to suit the profile of the soffit. This method of support to the formwork was generally preferred to the proprietary types or arch and slab centring. Where the design called for in-situ voided construction, the Contractor elected to use purpose-made expanded polystyrene void formers.

Aluminium alloy parapets were provided throughout the Contract.

Under the combined sponsorship of the Oxford University Department of External Studies and the Oxford City and County Museum, a special Research Group was set up to investigate potential archaeological sites on the line of route. During the design and construction of the motorway the Engineer and Contractor's staff cooperated with the Group to allow them to locate and excavate a number of interesting sites as follows: