The Gerrards Cross Bypass was the last section of the M40 in Buckinghamshire to be constructed. It brought the length of motorway from Stokenchurch, 28 kilometres (17 miles) east of Oxford, to Denham Roundabout, some 30 kilometres (19 miles) west of central London to 34 kilometres (21 miles).

In 1974, the motorway was extended 15.4 kilometres (9½ miles) towards Oxford with the completion of the Stokenchurch to Waterstock Crossroads section. The main contractor was the Amey Asphalt/Leonard Fairclough(AMEC) consortium, and the scheme was opened on the 23rd August 1973 by the Rt Hon John Peyton MP.

The Bypass began at the Beaconsfield Interchange, the eastern end of the Beaconsfield Bypass, where it is in deep cutting. About 2 kilometres to the east it crosses, at approximately original ground level, an area of sand and gravel pits, where a considerable amount of pre-contract work was needed to prepare a base for the motorway. Deep cutting is again encountered 1 kilometre further east, to the north of Hedgerley Green, before the road turns south-east on embankment across the A332 Windsor Road then runs eastwards north of Fulmer and along the Alder Bourne valley. At Rush Green the bypass enters the valley of the River Colne, which it traverses on high embankment to join the existing A40 east of the new interchange at Denham Roundabout.

Considerable care had to be taken on the siting and landscaping of the new road, as well as in the design of bridges and other structures. The aim was to tailor the motorway to the landscape, so that it appears to slide smoothly through the countryside while offering the motorist a stimulating visual experience. The design of the 14 bridges on this bypass were conceived from the viewpoint of the people who will see them most. The overbridges have open spans and simple tapering piers to emphasise for the motorist the continuing road ahead, while the abutment faces of the underbridges contain deeply recessed tapering features to counteract the tunnel effect of the structures.

Gerrards Cross Bypass incorporated an important innovation in its construction: the three-lane carriageways were of concrete, the surface of which was finished by a special machine to produce transverse grooves, designed to provide high-speed skid resistance under all weather conditions and to ensure rapid dispersal of surface water, thus minimising spray and the risk of aquaplaning. Random spacing of the grooves made it impossible for pure tones to be generated by vehicle tyres, which eliminated the objectionable high-pitched whine that can otherwise be produced. The grooving machine was the result of several years' research by the Cement and Concrete Association and this was the first time it has been used in the building of a public highway.

Pre-contract works

Earthworks

The problems of the alignment of the scheme were mainly on the centre section, since at the western extremity the route for Beaconsfield Bypass had already been decided, and at the eastern end the scheme would join the existing Western Avenue section of A40 at Denham. Two kilometres east of Beaconsfield a difficulty was encountered in an area of the Gerrards Cross Sand and Gravel Pits where over a length of some 600 metres gravel and sand had been worked and clay overburden excavated and dumped in heaps over the site. Water-filled holes up to 20 metres deep were formed by this operation, which obviously presented a serious obstruction to the earthworks side of the contract.

Pre-contract works were carried out here in order to give the main contractor a reasonable site on which to carry out his earthworks. Lump sum tenders were therefore invited from a number of earthmoving firms and the contract was secured by Larry Webb (Plant) Ltd of St Albans in the sum of £32,650.

The work consisted of regrading and compacting existing materials in the pit to form a base up to 10 metres high on which the final embankment could be built. Drainage works were also included to allow standing water to be drained into the deeper holes, whence it percolated into the underlying chalk. In spite of bad weather the contract was satisfactorily completed well within the contract period of six months, leaving a firm base for the main contractor.

Side road strengthening

The Buckinghamshire County Council carried out a considerable programme of side road widening and strengthening on the permitted haul routes to the motorway prior to the commencement of the main contract at a cost of approximately £70,000.

Topographical surveys

A 1/2500-scale aerial survey was carried out by W S Atkins and Partners in 1962, and the 1/500-scale aerial survey by Fairey Surveys Ltd in 1968.

Soil surveys

Le Grand Sutcliffe and Gell Ltd completed a site investigation in January 1969. After the publication of the 1969 edition of the MoT Specification, it was decided to supplement the information obtained from this survey, principally to obtain more detailed information in the cutting areas, and a further survey was completed in May 1970 by Ground Engineering Ltd, with a large programme of classification tests carried out by the Department's consultant testing engineers, Messrs Sandberg, at their site laboratory.

The following geological formations were present:

Contract documents

The contract documents were prepared in metric units, and based on the MoT Specification, 1969 edition, the MoT Method of Measurement, and included a working-day contract period. In this all the contractor's activities have to be shown on a network and a working day was a day spent working on an activity which was currently critical.

The bill of quantities was prepared by computer program on the Buckinghamshire County Council ICL computer and was printed from the computer print-out.

Alternative tenders were obtained for flexible and rigid carriageways, the latter being accepted as the lower tender. The tender sum for the whole contract was £5,387,974 and work commenced on 23 August 1971.

Roadworks

Drainage

There were no existing water-courses in the western section (Beaconsfield to Windsor Road) and the disposal of surface water in this area was by means of 54 soakaway bores into the underlying upper chalk with storage capacity provided by large precast concrete chambers. From Windsor Road eastwards there were outfalls to the Alder Bourne and the River Colne. The drainage system was designed for one year storm (RRL hydrograph method) using a computer program. All outfalls and design details were approved by the Thames Conservancy Board.

Earthworks

The total quantity of fill required was approximately 2,300,000 cubic metres, a large proportion of this being obtained from the site and the short-fall from local borrow pits negotiated by the contractor. Cutting slopes vary from 2:1 to 4:1 and embankment slopes from 2:1 to 3:1 depending on depth or height and the type of material.

The Transport and Road Research Laboratory carried out measurements and studies at the high embankment to the west of the Denham Roundabout relating to the construction of embankment with high-moisture-content clays.

Carriageways

Carriageways

The three-lane concrete carriageways were 11.0 metres wide with 3.3 metre wide hard shoulders of flexible surfacing on a lean concrete base, and a 4.0 metre central reserve, provided throughout with tensioned safety fencing. The concrete pavement was designed in accordance with Road Note 29 (2nd edition) and the spacing of joints modified in accordance with the 3rd edition, and the contractor elected to construct the motorway carriageways using unreinforced concrete.

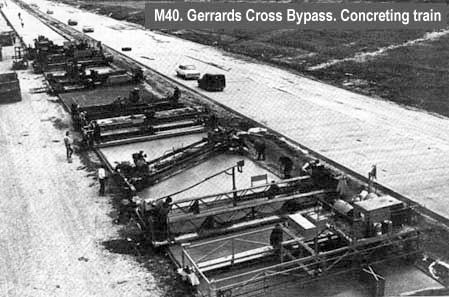

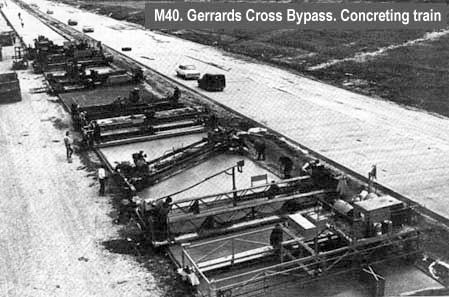

Aggregates for both the pavement concrete and the soil cement base were obtained locally from the contractor's own pits. Each concrete carriageway was paved by a conventional railed train (SGME) in abutting widths of two lanes and one lane. Two-course spreading and compaction was used, with contraction-joint dowelbars and longitudinal-joint tie-bars inserted into the compacted bottom-course concrete.

The Gerrards Cross Bypass contract marked the commercial debut of the CCA-Errut plastic concrete grooving machine for producing anti-skid texture on new concrete roads. This machine was the culmination of several years' research by the Cement and Concrete Association and was manufactured under licence by Errut Products Ltd. The effect of the transverse grooves formed by this finishing process was to provide high-speed skidding resistance under all weather conditions and to ensure rapid dispersal of surface water, thus minimising spray and the risk of aquaplaning. It was hoped that these characteristics would be achieved in use and prove to be long lasting. The pre-set random spacing of the grooves was designed so that no pure tones are generated by the vehicle travelling over the surface, thus the tyre noise is at an acceptable level, both within and outside the vehicle. This was an important development as the public in the past had found grooved roads objectionable due to their high-pitched tyre whine.

Side roads

There were 1.2 kilometres of dual two-lane carriageway diversion on the A412 to the south of Denham Roundabout, 5 kilometres of side road alterations and 2.8 kilometres of slip-road and roundabout construction at Denham. The side roads were designed in consultation with the highway authority (Buckinghamshire County Council) and were of flexible construction.

Lighting

A nominated subcontract was let for sign lighting and the road lighting required for the Denham Interchange area.

Services

The estimated cost of alterations to existing services was £450,000. These were particularly complex in the Denham Roundabout area and a service culvert was provided under the motorway embankment to accommodate some of the diversions.

As many alterations as possible were carried out precontract, including five Central Electricity Generating Board pylon crossings of the route.

Bridgeworks

There were a total of 14 bridge structures on the scheme, four four-span overbridges, one two-span overbridge, three single-span underbridges, three footbridges and three box-section underpasses (including a service culvert). There were in addition two retaining walls.

Overbridges

These bridges were seen mainly by people travelling at high speeds on the motorway and the general mass, proportion and outline were the factors that were the main interest for the motorist. The aesthetic concept for the overbridges was therefore to emphasise the continuing road ahead by open spans and simple tapering hammerhead piers. The forward sloping faces of the buried abutments and the tapering side-slope paving also echoed the pier shapes.

Precast-concrete fascia panels of exposed Mountsorrel granite aggregate carried the lines of the superstructure over the abutments and the copings were emphasised by Permwhite exposed aggregate precast-concrete units.

Four-span overbridges (Hedgerley Lane, Fulmer Road Hawkswood Lane, Hollybush Lane)

The width between parapets of these bridges was 1097 metres and the main spans varied from 20 metres to 24 metres. Skews were from 6° to 35°.

The deck spans were simply supported, each span comprising seven Preflex beams with an in-situ reinforced concrete slab spanning transversely. Service bays were provided between the outer two beams. The beams were supported on laminated rubber bearings. The expansion joints had epoxy-resin-mortar nosings with Neoprene compression seals and the parapets were of aluminium with epoxy-resin-coated mild-steel-mesh infilling.

The piers and abutments were of reinforced concrete and except for Hollybush Lane were founded on spread footings. At Hollybush Lane a deeper buried abutment founding at a similar level to the pier supports was provided, to allow possible future slip roads to pass under the bridge through the side spans. Lower bearing capacity of the clay at this bridge site necessitated the use of piled foundations, in-situ concrete bored piles being used.

Two-span overbridge (Hyde Farm)

This two-span structure accommodated a farm access road. Four Preflex beams per span were used in the deck to form a gentle vertical curve between the abutments, with the remaining treatment being similar to the fourspan overbridges. The width between parapets of this bridge is 6.19 metres and the spans were 25.5 metres.

Underbridges (Windsor Road Denham Roundabout West, Denham Roundabout East)

In contrast to the overbridges, these structures were seen by pedestrians in addition to other road-users. The aesthetic problems were therefore somewhat different and a single-span solution was found to be more appropriate at these three locations.

The spans vary from 21.16 metres to 23 metres and the width between parapets from 34.9 metres to 48.57 metres. Skews are from 12° to 17½°.

In view of the length of the abutments (at Denham Roundabout West they are 52 metres long) and to counteract the tunnel effect of the structures, it was felt that the flat planes should be relieved by formed shapes rather than by surface texturing. The abutment faces contained deeply recessed tapering features. The wingwall surfaces had a fluted form and were cantilevered from the abutment walls, eliminating the necessity for separate wing-wall foundations and buried structural members. The decks were of pre-tensioned concrete box-beams, transversely post-tensioned, and supported on laminated rubber bearings. The expansion joints had epoxy-resin-mortar nosings with Neoprene compression seals. The coping units were similar to those on the overbridges.

The steel parapets were of an energy-absorbing type consisting of tubular rails mounted on posts that pivot and contained an hydraulic shock-absorber. When the barrier was struck, the energy of the vehicle was dissipated in compressing the hydraulic shock-absorber.

The foundations were on steel H-piles. The Institute of Geological Sciences was consulted at an early stage in the foundation design and the Alder Bourne valley was noted as a likely situation for the occurrence of swallow holes. At the Windsor Road site, therefore, the piles were designed to penetrate through the dense gravel stratum and into the underlying block chalk as a precaution against the probable presence of swallowholes in the vicinity. The problem of driving through the 6.8-metres-thick stratum of gravel gave rise to the choice of pile type. The driving records subsequently appeared to confirm that swallow-holes were indeed present under the foundations and that the additional cost of the piling was justified.

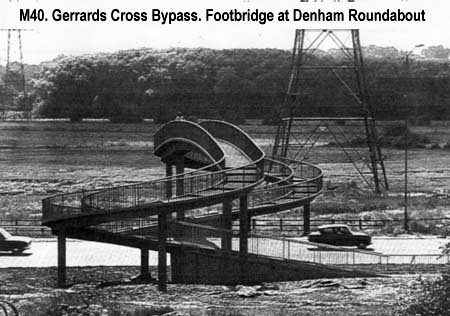

Footbridges

The three elegant footbridges located at the Denham Roundabout were 1.93 metres wide, with main spans of 19.75 metres and 22.75 metres. They were of steel box-girder construction with helical ramps and manufactured by the Butterley Engineering Company. The superstructure was carried on circular steel columns which in turn were supported on mass concrete column bases.

During the tender period, the Department of the Environment initiated the programme of steel boxgirder appraisals based on the Merrison Committee Interim Rules, and an appraisal of the box sections was carried out before the drawings were issued to the contractors.

Box underpasses (Denham Service Culvert, Fulmer Place, Mount Hill)

These were reinforced-concrete box-section buried structures with clear spans varying from 2.75 metres to 4.5 metres.

Denham Service Culvert, already referred to, carried gas and water mains, and agricultural underpasses were provided at Fulmer Place and Mount Hill Lane.

There were two retaining walls on the contract: the first, at Windsor Road, was a mass-gravity type retaining the embankment adjacent to the nearby houses; the second, on the realigned A412, was of reinforced concrete. This had been constructed to avoid undermining the footings of a Central Electricity Generating Board pylon. In addition, the foundation to one leg of the pylon was surcharged with a reinforced concrete weighting slab to compensate for material displaced by the new construction.

Contract details

| Section | Engineer | Contractor |

| Knaves Beech interchange | ERCU (Bucks SU) | Sydney Green |

| Gerrards Cross By-pass (J1 to J2) | ERCU (Bucks SU) | Amey Asphalt/Leonard Fairclough(AMEC) consortium |

| Beaconsfield By-pass (J2 to J3) | ERCU (Bucks SU) | Amey Asphalt/Leonard Fairclough(AMEC) consortium |

| High Wycombe By-pass Loudwater to Handycross(J4) |

Bucks CC | George Wimpey |

| Loudwater viaduct | Bucks CC | Reed and Malik |

| Handycross to Stokenchurch (J5) | Bucks CC | S Green/ Holland Hannen and Cubitts/Kier consortium |